Technical Parameters

| MT 1050S Automatic Deep Embossing & Hot Stamping & Die-Cutting Machine | |

| Model | MT-1050S Automatic Deep Embossing & Hot Stamping & Die-Cutting Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370 × 270) |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 750T |

| Max.working Speed | 7500P/H |

| Air requirements | 0.6~0.8mp 0.36m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<3mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 18.5Kw |

| Heating power | 27.8Kw |

| Servo total power | 16Kw |

| Total power | 67Kw |

| Working power | 35Kw |

| Weight | 23T |

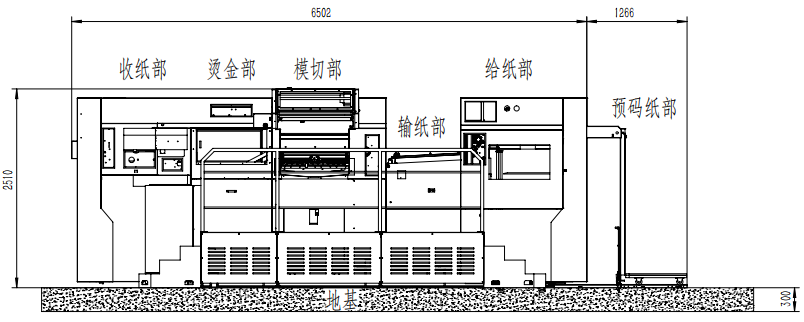

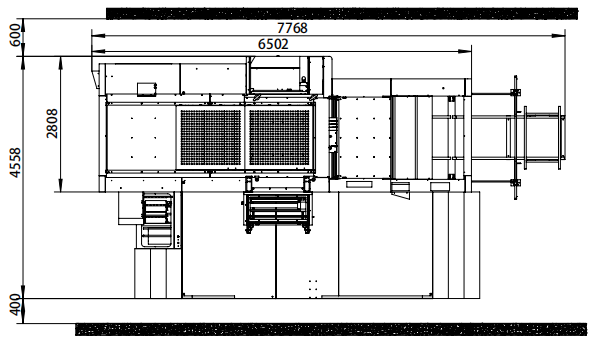

| Dimensions | 6502×2808×2510mm pedal width 1750mm |

Sketch

video

MT 1050S Automatic Deep Embossing, Hot Stamping & Die-Cutting Machine

The MT 1050S Automatic Deep Embossing, Hot Stamping & Die-Cutting Machine is a next-generation multifunctional post-press finishing equipment designed to meet the demands of modern high-end packaging and printing industries. It combines hot foil stamping, deep embossing, and die-cutting in one efficient, automated unit, providing unmatched productivity, precision, and decorative quality.

This machine is ideal for manufacturers seeking luxury finishing effects on packaging materials such as cosmetic boxes, wine cartons, gift boxes, book covers, and premium labels. With a focus on automation, accuracy, and safety, the MT 1050S helps printing enterprises enhance production capability and deliver refined visual and tactile experiences.

The design of the MT 1050S follows the principle of integration, precision, and reliability. It combines multiple finishing processes—foil stamping, embossing, and die-cutting—into a single machine to minimize manual handling, reduce alignment errors, and improve production efficiency.

By performing hot stamping, embossing, and die-cutting simultaneously, the MT 1050S eliminates the need for multiple machines and repeated setup, enabling faster turnaround and lower operational costs.

The machine frame is made from high-strength cast iron, ensuring minimal vibration, excellent pressure stability, and long service life. Every key component— from the feeding section to the delivery system—has been optimized for micron-level registration accuracy.

Equipped with servo-driven registration, PLC control, and a touch-screen human–machine interface (HMI), the MT 1050S allows precise control of temperature, pressure, foil feeding length, and die-cutting pressure with real-time feedback and easy operation.

The design emphasizes operator safety and convenience with automatic lubrication, multiple emergency stop buttons, safety doors with sensors, and fault-detection systems, ensuring both safety and high efficiency during production.

| Feature | Description / Benefit |

|---|---|

| 3-in-1 Function | Integrates hot stamping, embossing, and die-cutting for one-pass finishing |

| High Precision Registration | Servo motor control ensures accurate positioning and reduced waste |

| Multi-Zone Temperature Control | Ensures uniform heat distribution for consistent foil transfer |

| Automatic Foil Feeding | Intelligent unwinding, tension, and rewinding systems improve foil utilization |

| Heavy-Duty Structure | Stable frame minimizes vibration for smooth and accurate stamping |

| User-Friendly Interface | Touch-screen control panel for easy parameter setup and monitoring |

| Efficient Die-Cutting Unit | Precise cutting edges for clean, professional product finishing |

| Safety & Monitoring System | Automatic fault detection and overload protection |

| Model | MT 1050S |

|---|---|

| Max Sheet Size | 1050 × 750 mm |

| Min Sheet Size | 400 × 350 mm |

| Max Stamping Area | 1040 × 730 mm |

| Max Cutting Area | 1040 × 730 mm |

| Foil Feeding Shafts | 3 (customizable) |

| Max Speed | 6000 sheets/hour |

| Max Pressure | 300 tons |

| Embossing Depth | Up to 4.0 mm |

| Temperature Control Range | 0°C – 200°C |

| Paper Thickness | 90 – 2000 g/m² |

| Power Supply | 380V / 50Hz / 20 kW |

| Machine Dimensions (L×W×H) | 5800 × 2600 × 2200 mm |

| Net Weight | Approx. 12,000 kg |

Specifications may vary slightly based on configuration and customization.

The MT 1050S is engineered for a wide range of luxury packaging and decorative printing applications:

Cosmetics packaging

Wine and liquor boxes

High-end gift boxes

Stationery products

Book covers and certificates

Labels and promotional materials

Its ability to combine metallic stamping, tactile embossing, and precise cutting in one pass creates outstanding visual effects that strengthen brand identity and product value.

To ensure reliability and longevity, each MT 1050S machine is manufactured under strict quality control standards:

All mechanical parts are produced using CNC machining centers for perfect fit and tolerance control. This precision ensures stable pressure and consistent registration during operation.

Each machine undergoes a three-stage inspection process:

Mechanical assembly verification

Electrical and control system testing

Performance and durability trials

Before delivery, the MT 1050S is tested for temperature accuracy, pressure uniformity, and foil feeding precision to guarantee factory-level consistency. Every unit must pass a continuous 8-hour test run before being shipped.

The equipment conforms to international safety and performance standards, including CE certification, ensuring global compatibility and safety assurance.

Regular maintenance is essential for keeping your MT 1050S operating smoothly and extending its lifespan. Below are recommended maintenance guidelines:

Clean the working area, removing foil dust and paper scraps.

Check oil levels in the automatic lubrication system.

Wipe the heating plate and ensure even temperature distribution.

Inspect foil feeding rollers for smooth rotation.

Check all bolts and fasteners for tightness.

Clean the air filters and check pneumatic valves.

Inspect electrical connections and ensure proper grounding.

Test safety sensors and emergency stops.

Calibrate the temperature and pressure systems.

Check the condition of the drive belts and replace if worn.

Lubricate moving parts such as guide rails and gears.

Examine registration alignment and adjust if needed.

Conduct a complete inspection of mechanical, electrical, and pneumatic systems.

Replace consumable parts such as seals, filters, and lubrication oil.

Perform comprehensive performance testing to verify operation efficiency.

Safety Note: Always disconnect the power supply and release pressure before performing maintenance.

Pre-Heating:

Allow the heating plate to reach target temperature before feeding sheets. Uneven heating can affect foil transfer quality.

Foil Selection:

Choose high-quality foil that matches substrate type and design requirements. Poor foil can cause incomplete transfer.

Pressure Adjustment:

Adjust pressure gradually to prevent over-embossing or material deformation.

Trial Run:

Perform a few test runs before full production to fine-tune registration and foil feeding.

Clean Workspace:

Maintain a dust-free environment to avoid contamination on printed surfaces.

The MT 1050S is built to maximize productivity and minimize waste through its intelligent automation and precise mechanical coordination.

The feeder uses vacuum suction and servo control for accurate sheet feeding. The delivery section stacks finished products neatly and safely without manual intervention.

The system supports multiple foil rolls, enabling simultaneous multi-color or multi-pattern stamping in one operation.

The embossing unit features uniform pressure distribution technology, ensuring consistent depth and clarity across the entire stamping area.

The digital HMI provides real-time monitoring of running parameters, temperature, and alarms. Operators can store job settings for quick recall and consistent production.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Foil not transferring evenly | Uneven temperature or low pressure | Adjust temperature zones or increase pressure |

| Misalignment between foil and die-cut | Incorrect registration or foil feeding error | Recalibrate servo system and foil tension |

| Paper jam | Improper feeding setup or static | Clean feeder, adjust air suction, or slow speed |

| Embossing too shallow | Insufficient pressure or incorrect depth | Increase pressure or adjust embossing plate |

| Foil wrinkle or tear | Excessive tension | Reduce tension and ensure smooth unwinding |

Only trained personnel should operate the machine.

Always wear heat-resistant gloves and safety goggles when handling heated parts.

Keep the work area dry and clean.

Do not bypass safety sensors or covers.

Use the emergency stop button immediately in case of abnormal sound or movement.

The machine’s built-in protection systems—such as overload detection, temperature alarms, and automatic shutoff—ensure operator safety and minimize downtime.

The MT 1050S is packed in a fumigation-free wooden crate with anti-rust protection and foam cushioning. Each shipment includes:

Machine body and accessories

Electrical schematics and operation manuals

Maintenance toolkit

Delivery Time: Usually 45–60 days after order confirmation.

Installation: On-site installation and operator training are available upon request.

Technical Support: 24-hour online service and video assistance.

Training: Free operational and maintenance training for customer technicians.

Spare Parts: Long-term availability of genuine spare parts.

Warranty: 12-month warranty for non-consumable components.

Our dedicated service team ensures continuous machine operation and rapid response to customer needs worldwide.

One-pass multifunctional operation reduces equipment costs.

High precision and stability ensure flawless finishing.

Automated systems improve speed, consistency, and operator comfort.

Durable construction supports long-term heavy-duty use.

Global after-sales network provides dependable support.

The MT 1050S is not just a machine—it’s a complete finishing solution designed to help packaging producers achieve higher efficiency, reduced waste, and superior decorative results.

The MT 1050S Automatic Deep Embossing, Hot Stamping & Die-Cutting Machine represents the future of intelligent post-press finishing. By integrating three high-value processes into one system, it delivers efficiency, precision, and premium quality for today’s competitive packaging industry.

Whether producing luxury cosmetic boxes, wine labels, or high-end promotional materials, the MT 1050S ensures every sheet reflects perfection in both texture and detail.

For manufacturers pursuing innovation, speed, and excellence, this machine is the ultimate investment in productivity and craftsmanship.

This website uses cookies to ensure you get the best experience on our website.