Technical Parameters

| MTJ 1050 Automatic deep embossing and hot stamping machine | |

| Model | MTJ-1050 Automatic Deep Embossing And Hot Stamping Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 750T |

| Max.working Speed | 7600P/H |

| Air requirements | 0.7~1.0Mp 0.6m³ |

| Paper thickness | White card/plastic sheet:0.1~1.8mm Grey board:<4mm Corrugated paper:<5mm |

| Gripper range | 3~8mm |

| First die line distance from template | 15mm |

| Motor power | 18.5Kw |

| Total Power | 67Kw |

| Total heating power | 27.8Kw |

| Servo total power | 16Kw |

| Working power | 35Kw |

| Weight | 23T |

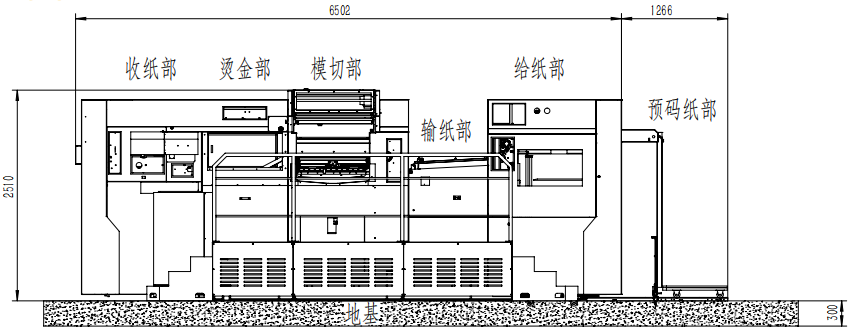

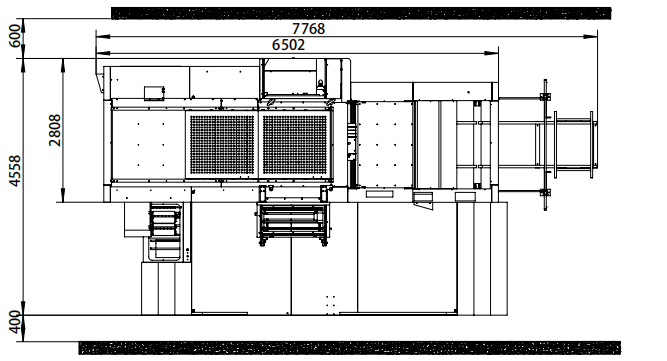

| Dimensions | 6502×2808×2510mm pedal width1750mm |

Sketch

MTJ 1050 Automatic deep embossing and hot stamping machine

The MTJ 1050 Automatic Deep Embossing and Hot Stamping Machine is an advanced, high-precision post-press processing equipment designed for luxury packaging and high-end printing applications. Combining deep embossing, hot foil stamping, and die-cutting functions, it enables users to achieve refined surface textures and metallic effects that elevate product presentation.

Engineered with cutting-edge automation technology, precise temperature and pressure control, and a user-friendly interface, the MTJ 1050 delivers stable performance, high registration accuracy, and exceptional production efficiency. It is widely used in packaging for cosmetics, wine, tobacco, electronics, stationery, and gift boxes—where premium visual and tactile effects are essential.

The MTJ 1050 integrates hot stamping and deep embossing in one system, reducing the need for multiple machines and manual transfers. This integrated design ensures alignment precision between embossing and foil layers, creating superior embossed metallic finishes in a single pass.

Equipped with servo-driven feeder and registration control, the machine ensures accurate positioning for both foil and substrate, minimizing waste and guaranteeing consistent results even during high-speed production.

The MTJ 1050 adopts a multi-zone heating system with intelligent temperature control, ensuring even heat distribution across the stamping plate. Pressure is adjustable based on substrate thickness, enabling smooth transitions from fine paper to thick cardboard without deformation or overheating.

The foil unwinding, tension control, and rewinding are all automatically managed, supporting multiple foil rolls and precise feeding steps. This system optimizes foil utilization and prevents wrinkling, saving costs and improving visual quality.

Operators can easily set, monitor, and adjust all parameters through an intuitive touch screen control panel. Real-time data such as temperature, pressure, and running speed are displayed for easy management.

Built from a reinforced cast-iron frame, the MTJ 1050 offers low vibration, reduced noise, and reliable operation under continuous production conditions. The machine structure ensures durability and long-term stability.

The machine includes multiple safety sensors, emergency stop functions, and automatic fault detection to ensure operator safety and prevent damage during abnormal operation.

| Item | Specification |

|---|---|

| Model | MTJ 1050 Automatic Deep Embossing and Hot Stamping Machine |

| Max Sheet Size | 1050 × 750 mm |

| Min Sheet Size | 400 × 350 mm |

| Max Stamping Area | 1040 × 730 mm |

| Max Stamping Speed | 6000 sheets/hour |

| Foil Feeding Shaft | 3 shafts (standard) |

| Temperature Control Range | 0°C – 200°C |

| Max Embossing Depth | 4.0 mm (adjustable) |

| Paper Thickness | 90 – 2000 g/m² |

| Max Pressure | 300 tons |

| Power Supply | 380V / 50Hz / 20 kW |

| Machine Dimensions | 5800 × 2600 × 2200 mm |

| Net Weight | Approx. 12,000 kg |

(Specifications may vary depending on configuration and customer requirements.)

The MTJ 1050 is suitable for a wide range of premium packaging and printing applications, including:

Cosmetic boxes

Perfume packaging

Wine and liquor boxes

Luxury gift boxes

Stationery and greeting cards

Book covers

Labels and certificates

By combining deep embossing and hot stamping, the machine produces multi-dimensional metallic effects that enhance brand value and visual appeal.

Before operation, ensure the machine is properly cleaned, lubricated, and powered. Check the stamping plate, die, and foil roll for correct installation. Adjust the embossing depth and foil tension based on material thickness and design requirements.

Load the sheets into the automatic feeder. Adjust the feeder guides and air-suction settings to ensure smooth sheet pickup and alignment. Verify that the registration sensors detect each sheet accurately.

Use the touch-screen control panel to set the required temperature, pressure, and stamping dwell time. Allow the heating plate to reach the target temperature before initiating stamping.

Select the foil feeding length and step according to the artwork design. The automatic foil system will handle unwinding, tensioning, and rewinding during operation.

Perform a test cycle to check registration accuracy, foil coverage, and embossing depth. Make fine adjustments to temperature or pressure if necessary.

Once parameters are optimized, start full-speed production. The automatic feeding, stamping, and delivery systems operate continuously, ensuring stable output.

Finished sheets are neatly stacked in the delivery section. Operators should periodically inspect product quality, ensuring consistency and precision.

| Feature | Benefit |

|---|---|

| Dual stamping and embossing | Reduced setup time and superior alignment |

| Servo registration system | High accuracy and minimal waste |

| Multi-zone heating control | Consistent stamping quality |

| Heavy-duty frame | Long-lasting stability and precision |

| Touch-screen interface | Easy operation and parameter adjustment |

| Safety protection system | Operator safety and machine longevity |

Proper maintenance is essential to maintain performance and extend machine lifespan. The following maintenance schedule is recommended:

Clean foil residues, dust, and paper scraps from the working area.

Check lubrication points and add oil where necessary.

Verify that the heating plate and temperature sensors are functioning correctly.

Inspect foil feeding shafts and ensure smooth operation.

Check for loose bolts and tighten if needed.

Inspect pneumatic and electrical connections.

Clean filters and replace if clogged.

Ensure all sensors and switches are responsive.

Calibrate temperature and pressure systems.

Examine the main drive belt and replace it if signs of wear appear.

Check the registration accuracy and perform system diagnostics.

Conduct a full system inspection, including electrical circuits, hydraulic system, and mechanical components.

Replace consumables such as seals, filters, and lubrication oil.

Verify software updates and recalibrate control systems.

Tip: Always power off and disconnect the machine before any maintenance or cleaning operation.

Safety should always be the top priority during operation. Please observe the following:

Training Requirement:

Only trained operators should use or adjust the MTJ 1050 machine.

Protective Equipment:

Operators should wear safety gloves, glasses, and appropriate clothing.

Temperature Awareness:

The heating plate can reach high temperatures (up to 200°C). Avoid direct contact.

Emergency Stop Usage:

In case of abnormal noise, vibration, or jamming, press the emergency stop button immediately.

Electrical Safety:

Disconnect the main power before servicing or replacing electrical parts.

Work Area Cleanliness:

Keep the surrounding area free of debris and flammable materials.

| Problem | Possible Cause | Solution |

|---|---|---|

| Uneven stamping | Temperature imbalance or uneven pressure | Check heating zones and adjust pressure |

| Foil misalignment | Registration sensor error or foil tension issue | Calibrate sensor; adjust tension |

| Foil wrinkles | Excess tension or uneven feeding | Reduce foil tension and check feeding alignment |

| Incomplete embossing | Insufficient pressure or wrong depth setting | Increase pressure or adjust die height |

| Paper jam | Improper feeding or static | Clean feeder, adjust air suction, reduce speed |

Efficiency: One-pass operation for embossing and stamping saves time and cost.

Precision: Servo registration and advanced control systems ensure perfect alignment.

Durability: Industrial-grade components guarantee long service life.

Flexibility: Suitable for multiple materials and thicknesses.

Automation: Reduces manual labor and increases production consistency.

These advantages make the MTJ 1050 an ideal solution for manufacturers seeking premium, high-efficiency post-press processing equipment.

The machine is securely packed in a fumigation-free wooden case or reinforced steel frame, ensuring safe transportation. All key components are covered with moisture-proof film to prevent corrosion.

Before shipment, the machine undergoes strict factory testing and quality inspection, including trial runs, calibration, and safety verification.

Technical Support: Online and on-site installation guidance.

Training: Operation and maintenance training for new operators.

Spare Parts: Long-term supply of original parts and accessories.

Warranty: 12-month warranty covering manufacturing defects (excluding consumables).

Response Time: 24-hour online service response and global support availability.

The MTJ 1050 Automatic Deep Embossing and Hot Stamping Machine delivers exceptional precision, productivity, and visual quality, making it the preferred equipment for manufacturers in the luxury packaging industry.

With integrated design, advanced automation, and robust construction, it enables consistent, high-value output that enhances brand image and customer satisfaction.

Whether you are producing premium gift boxes, cosmetic packaging, or foil-stamped promotional materials, the MTJ 1050 provides a reliable, efficient, and cost-effective solution for your production line.

This website uses cookies to ensure you get the best experience on our website.