Technical Parameters

| MY 1060S Automatic Deep Embossing And Die-Cutting Machine | |

| Model | MY-1060S Automatic Deep Embossing And Die-Cutting Machine |

| Max.paper size | 1080×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370 × 270) |

| Max.die-cutting size | 1070×770mm |

| Die-cutting precision | ±0.09mm |

| Max.working pressure | 680T |

| Max.working speed | 7500P/H |

| Air requirementsSpeed | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey boardGrey board:<3mm Corrugated paper:<6mm |

| Gripper rangespeed | 3~7mm |

| Motor power | 17Kw |

| Heating power | 21Kw |

| Total power | 44Kw |

| Working power | 25Kw |

| Weight | 17T |

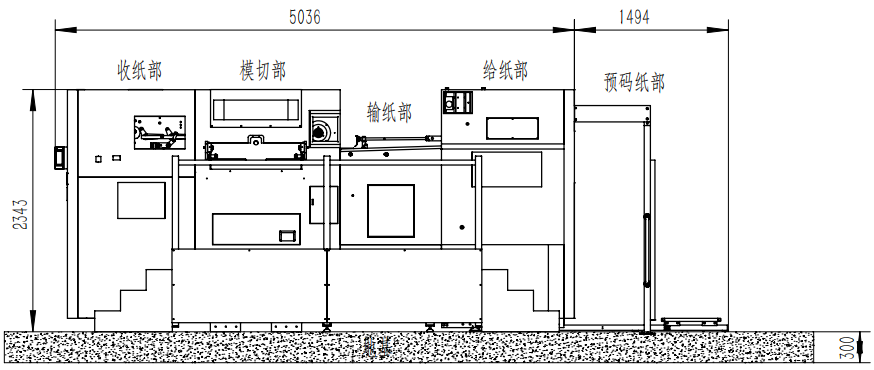

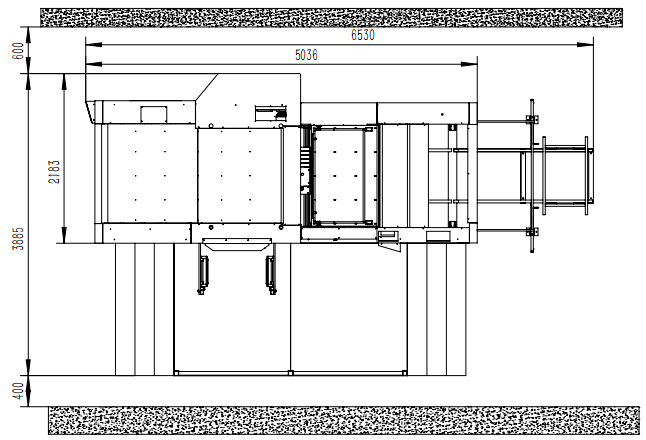

| DimensionsDimensions | 5036×2183×2343mm pedal width 1710mm |

Sketch

MY 1060S Automatic Deep Embossing and Die-Cutting Machine: Professional Overview

The MY 1060S Automatic Deep Embossing and Die-Cutting Machine is a state-of-the-art industrial machine designed for high-precision embossing and die-cutting of paper, cardboard, and other materials. Its automatic operation, combined with robust structural design, ensures efficiency, accuracy, and consistent quality in large-scale production environments. This comprehensive guide provides detailed insights into its features, structural components, maintenance practices, and packaging specifications.

The MY 1060S integrates multiple advanced technologies to deliver superior performance for industrial embossing and die-cutting. The following table summarizes its main features:

| Feature | Description |

|---|---|

| Automatic Operation | Equipped with PLC and touchscreen control, enabling fully automated embossing and die-cutting cycles. |

| High Precision | Accuracy within ±0.05 mm, suitable for intricate embossing patterns and fine die-cut shapes. |

| Adjustable Pressure | Hydraulic system allows precise adjustment of pressing pressure according to material type and thickness. |

| Speed Control | Adjustable working speed from 0–60 sheets/min, enhancing production flexibility. |

| Safety Mechanisms | Emergency stop buttons, safety guards, and overload protection ensure operator safety. |

| Energy Efficiency | Optimized hydraulic and electrical components minimize energy consumption. |

| Versatile Material Compatibility | Works efficiently on paper, cardboard, PVC sheets, leather, and other embossable materials. |

SEO Keywords: Automatic embossing machine, die-cutting machine, industrial embossing equipment

The MY 1060S is engineered for durability, ease of maintenance, and precision performance. Its main structural components include:

High-strength steel construction ensures stability and minimizes vibrations during operation.

Powder-coated finish prevents corrosion and enhances longevity.

Integrated leveling feet for smooth installation on uneven floors.

Provides consistent pressure for deep embossing and cutting.

Equipped with an adjustable pressure valve, allowing operators to fine-tune pressure based on material type.

Includes oil filter and cooler for reliable, long-term operation.

Touchscreen interface with PLC control system.

User-friendly design allows for quick selection of patterns, cutting depth, and cycle speed.

Stores up to 50 pre-set programs for rapid workflow changes.

Interchangeable die holders accommodate a variety of cutting plates.

Precision alignment ensures accurate die placement on each sheet.

Embossing rollers with adjustable depth control achieve consistent embossing patterns.

Automatic feeding system reduces manual labor and ensures accurate sheet placement.

Anti-jam sensors prevent paper misfeeds.

Delivery system includes stacker with adjustable height, allowing smooth collection of finished sheets.

Regular maintenance of the MY 1060S ensures optimal performance and extends the machine's operational lifespan. The following practices are recommended:

Clean the feeding and delivery sections to prevent material residue buildup.

Check hydraulic oil level and top up if necessary.

Inspect die holders and embossing rollers for wear or damage.

Ensure emergency stop buttons and safety guards are functional.

Lubricate moving components such as gears, chains, and bearings.

Inspect electrical wiring for signs of wear or loose connections.

Test pressure control and hydraulic valves for consistent operation.

Replace hydraulic oil filter to maintain system efficiency.

Check alignment of die-cutting module and embossing rollers.

Inspect machine frame for any structural stress or loose bolts.

Tips for Extended Longevity:

Avoid exceeding recommended sheet thickness.

Operate at recommended speed for the material type.

Store the machine in a dry, temperature-controlled environment when not in use.

For safe transportation and storage, the MY 1060S is packaged with care. Standard packaging includes:

| Packaging Component | Description |

|---|---|

| Wooden Crate | Reinforced plywood crate with foam padding to protect machine from impacts. |

| Shrink Wrap | Protects control panel and sensitive components from dust and moisture. |

| Internal Bracing | Secures moving parts during transit to prevent damage. |

| Optional Accessories Pack | Includes spare die holders, spare hydraulic filter, and maintenance toolkit. |

Shipping Dimensions and Weight:

Crate Dimensions: 3200 mm × 1500 mm × 1800 mm

Net Weight: 2200 kg

Gross Weight (with packaging): 2500 kg

SEO Keywords: industrial machine packaging, embossing machine shipping, die-cutting machine delivery

The MY 1060S is widely used in industries requiring precision embossing and cutting, including:

Packaging Industry: Cardboard and paperboard packaging for cosmetics, electronics, and luxury goods.

Printing Industry: Creating embossed logos, patterns, and textured finishes on printed materials.

Stationery Manufacturing: Producing high-quality notebooks, cards, and decorative paper.

Leather and PVC Goods: Embossing patterns on leather covers, wallets, and PVC sheets.

Industrial Prototyping: Custom die-cutting for product prototypes and model-making.

Full Automation: Reduces labor costs and ensures consistent output.

High Precision: Suitable for detailed embossing and complex die-cut patterns.

Durable Design: Steel frame and reinforced components reduce maintenance frequency.

Energy Efficiency: Low power consumption with advanced hydraulic design.

Versatility: Compatible with multiple materials and sheet sizes.

User-Friendly Interface: Simplifies operations for operators of varying skill levels.

| Parameter | Specification |

|---|---|

| Maximum Sheet Size | 1060 mm × 760 mm |

| Minimum Sheet Size | 300 mm × 200 mm |

| Die-Cutting Pressure | 0–50 tons (adjustable) |

| Embossing Depth | 0–12 mm (adjustable) |

| Working Speed | 0–60 sheets/min |

| Power Supply | 380V / 50Hz / 3 Phase |

| Hydraulic System | 5.5 kW, 50 L oil tank |

| Machine Dimensions | 2800 mm × 1400 mm × 1700 mm |

| Net Weight | 2200 kg |

Training Operators: Ensure operators are trained in using PLC and safety features.

Material Testing: Test new materials on low-speed settings before full production.

Regular Inspection: Keep a checklist of daily, weekly, and monthly maintenance tasks.

Spare Parts Management: Maintain essential spare parts like die holders, filters, and hydraulic oil to reduce downtime.

The MY 1060S Automatic Deep Embossing and Die-Cutting Machine is a versatile and reliable solution for industries demanding high-precision embossing and die-cutting. Its combination of advanced automation, robust structure, and user-friendly controls ensures superior performance, energy efficiency, and minimal downtime. With proper maintenance and handling, this machine can serve as a cornerstone of modern production workflows in packaging, printing, and stationery industries.

This website uses cookies to ensure you get the best experience on our website.