Technical Parameters

| MP 1050S Automatic Deep Embossing & Stripping & Die-Cutting Machine | |

| Model | MP-1050S Automatic Deep Embossing & Stripping & Die-Cutting Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370 ×270) |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 750T |

| Max.working speed | 8000P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<3mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 18.5Kw |

| Heating power | 27.8Kw |

| Total power | 52KW |

| Working power | 30Kw |

| Weight | 18T |

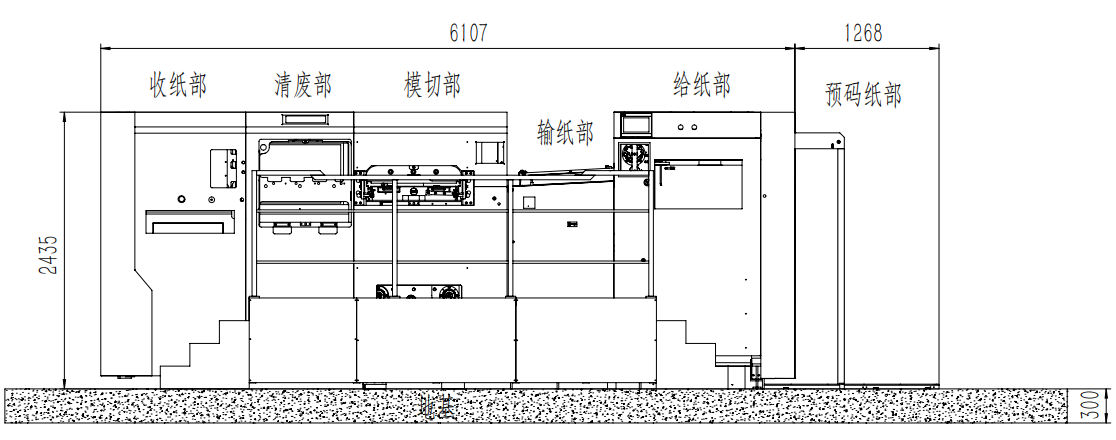

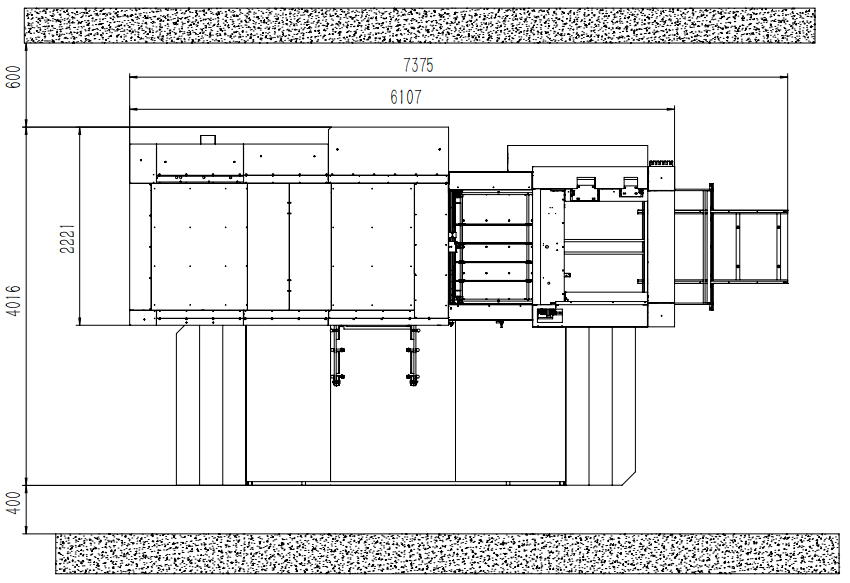

| Dimensions | 6107×2221×2435mm pedal width 1750mm |

Sketch

MP 1050S Automatic Deep Embossing & Stripping & Die-Cutting Machine

The MP 1050S Automatic Deep Embossing & Stripping & Die-Cutting Machine is a high-performance, fully automated solution designed for modern packaging and printing industries. Combining deep embossing, fully automatic stripping, and precise die-cutting, the MP 1050S ensures consistent, professional-quality output for a wide range of materials, including cardboard, paperboard, laminated sheets, and specialty printed materials.

Equipped with a durable steel frame, intelligent PLC control system, and multiple safety protections, this machine delivers high-speed operation, reduced labor, and superior precision, making it ideal for luxury packaging, folding cartons, labels, and specialty displays.

The MP 1050S offers several technical advantages that distinguish it in the packaging machinery market:

Deep Embossing Capability

Provides high-quality embossing with uniform depth and clarity.

Supports a variety of embossing patterns, from simple logos to complex designs.

Fully Automatic Stripping System

Removes waste efficiently, reducing manual labor and production errors.

Servo-controlled stripping ensures precise alignment for clean sheets.

Precision Die-Cutting

Advanced crankshaft and pressure distribution system deliver ±0.1 mm cutting accuracy.

Minimizes material waste and ensures professional finishing.

High-Speed Production

Capable of processing up to 6,500 sheets per hour depending on material and sheet size.

Optimized feeding and delivery systems maintain continuous operation.

Durable and Stable Construction

Reinforced steel frame reduces vibration and improves longevity.

Industrial-grade components ensure reliable long-term performance.

User-Friendly Intelligent Control

PLC system with HMI touchscreen interface simplifies operation.

Memory function allows storage of parameters for repeated jobs.

Multi-language interface supports global operators.

| Feature | Specification |

|---|---|

| Model | MP 1050S Automatic Deep Embossing & Stripping & Die-Cutting Machine |

| Max Sheet Size | 1050 × 750 mm |

| Min Sheet Size | 450 × 400 mm |

| Max Embossing Pressure | 300 tons |

| Die-Cutting Accuracy | ±0.1 mm |

| Maximum Speed | Up to 6,500 sheets/hour |

| Stripping System | Fully automatic top and bottom stripping |

| Feeding System | Front-edge feeder with air-assist |

| Control System | PLC with HMI touchscreen |

| Safety Features | Emergency stop, photoelectric protection, overload sensors |

| Applications | Luxury packaging, folding cartons, labels, specialty displays |

The MP 1050S is designed with precision, durability, and efficiency in mind. Each section of the machine plays a crucial role in maintaining consistent production quality.

The front-edge feeder ensures accurate sheet alignment and smooth feeding.

Air-assist nozzles stabilize thin sheets to prevent misfeeds.

Adjustable guides accommodate different sheet sizes and thicknesses.

Non-stop feeding reduces downtime and improves production efficiency.

The deep embossing system is the core feature of the MP 1050S.

Hydraulic or pneumatic pressure provides uniform embossing depth.

Reinforced frame and cutting plates prevent deformation under high pressure.

Automatic pressure adjustment ensures consistent embossing across all sheets.

Fully automatic stripping pins remove waste efficiently, delivering clean finished sheets.

Top and bottom stripping reduces manual handling.

Servo-controlled movement ensures precise alignment.

Quick-change stripping pins allow rapid job transitions.

The die-cutting platform provides high-precision cutting while minimizing material waste.

Crankshaft system distributes pressure evenly.

Durable die-cutting plates extend operational lifespan.

Optional tooling accommodates complex shapes and specialty designs.

The delivery unit ensures smooth collection and stacking of finished sheets.

Non-stop stacking system supports high-speed operation.

Alignment sensors maintain neat stacking of embossed and die-cut sheets.

Air-cushion options protect delicate materials from scratches.

The machine uses a PLC-based intelligent control system with an HMI touchscreen.

Multi-language support for global operators.

Real-time fault display simplifies troubleshooting.

Production memory allows quick setup for recurring jobs.

Regular maintenance is essential to ensure optimal performance and longevity.

Clean the feeder, die-cutting plates, and stripping pins to remove paper dust.

Check lubrication points and apply recommended oil.

Verify air pressure in nozzles and feeders.

Inspect safety sensors and emergency stops for proper function.

Inspect belt and chain tension and adjust as needed.

Lubricate bearings, guide rails, and moving joints.

Tighten loose mechanical fasteners.

Check stripping system alignment.

Examine die-cutting plates for wear or deformation.

Test PLC and HMI responsiveness.

Inspect electrical wiring for corrosion or loose connections.

Replace lubricants and hydraulic oil according to manufacturer specifications.

Conduct full system calibration, including embossing pressure and cutting accuracy.

Arrange certified service inspection.

To maximize productivity and maintain high-quality output, operators should follow these guidelines:

Material Selection: Use sheets compatible with recommended thickness and density.

Machine Warm-Up: Allow 10–15 minutes for hydraulic and control systems to stabilize.

Batch Parameters: Save job settings in HMI memory for repeated production runs.

Safety Compliance: Always wear PPE and never bypass interlocks.

Operator Training: Provide regular instruction on setup, operation, and troubleshooting.

Keep hands away from moving parts.

Do not operate without safety covers in place.

Immediately stop the machine if abnormal sounds or vibrations occur.

Keep the production area clean and free from obstacles.

Avoid overloading with sheets exceeding recommended size or thickness.

The MP 1050S is suitable for a wide range of packaging and printing applications:

Luxury Packaging – Embossed boxes for cosmetics, chocolates, and premium goods.

Folding Cartons – High-quality cartons for pharmaceuticals and food packaging.

Labels and Paperboard Displays – Precision die-cutting for marketing and retail displays.

Specialty Laminated Sheets – Custom shapes and embossed designs for branding purposes.

Its combination of automatic stripping, deep embossing, and precision die-cutting makes it ideal for both small-scale specialty production and large-volume industrial manufacturing.

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.