Technical Parameters

| MP 1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine | |

| Model | MP-1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine |

| Max.paper size | 1080×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370× 270) |

| Max.die-cutting size | 1070×770mm |

| Die-cutting precision | ±0.09mm |

| Max.working pressure | 680T |

| Max.working speed | 7500P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<3mm Corrugated paper:<6mm |

| Gripper range | 3~7mm |

| Motor power | 17Kw |

| Heating power | 21Kw |

| Total power | 44Kw |

| Working power | 25Kw |

| Weight | 18T |

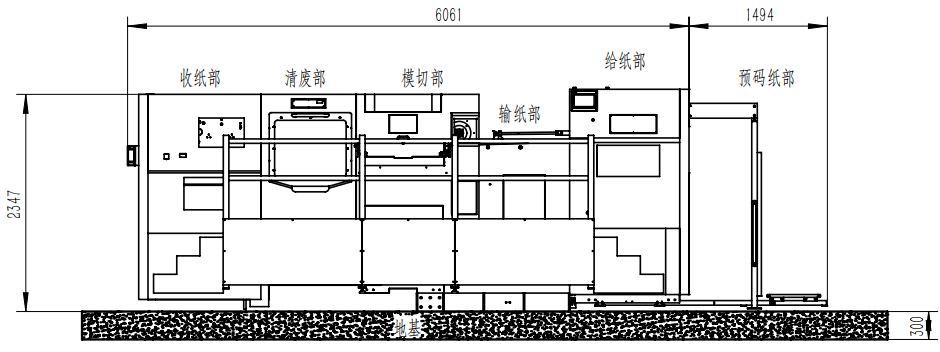

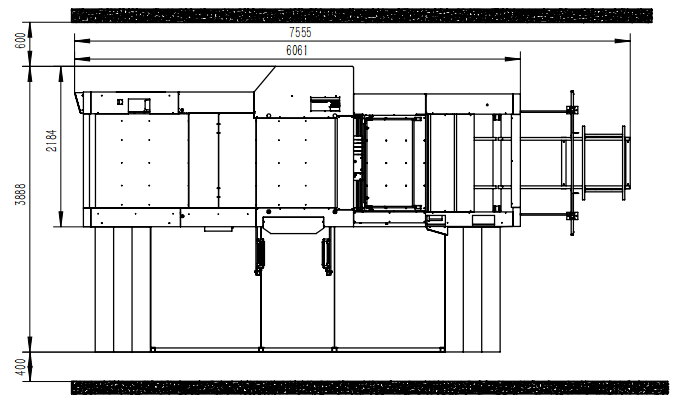

| Dimensions | 6061×2184×2347mm pedal width 1710mm |

Sketch

MP 1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine

The MP 1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine is an advanced high-speed solution designed for modern packaging and printing industries. Combining deep embossing capabilities, fully automatic stripping, and precise die-cutting, this machine ensures consistent, high-quality results for cardboard, paperboard, and laminated sheets.

With its durable steel frame, intelligent control system, and safety features, the MP 1060S reduces labor costs, improves efficiency, and supports the production of luxury packaging, folding cartons, and specialty printed materials. Its versatile design makes it suitable for a wide range of materials and production environments.

| Feature | Specification |

|---|---|

| Model | MP 1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine |

| Max Sheet Size | 1060 × 760 mm |

| Min Sheet Size | 450 × 400 mm |

| Max Embossing Pressure | 300 tons |

| Die-Cutting Accuracy | ±0.1 mm |

| Max Speed | Up to 6,500 sheets/hour |

| Stripping System | Fully automatic top and bottom stripping |

| Feeding System | Front-edge feeder with air-assist |

| Control System | PLC with HMI touchscreen |

| Safety Features | Emergency stop, photoelectric protection, overload sensors |

| Applications | Luxury packaging, folding cartons, labels, embossed paperboard |

The MP 1060S is designed for precision, durability, and efficiency. Each section of the machine is engineered to maintain consistent performance under high-speed production conditions.

The front-edge feeder ensures smooth and accurate sheet alignment.

Air-assist nozzles stabilize thin sheets and prevent misfeeds.

Non-stop feeding system reduces production downtime.

Adjustable guides accommodate different sheet sizes and thicknesses.

The core feature of the MP 1060S is its high-precision deep embossing system.

Hydraulic or pneumatic pressure provides consistent embossing depth.

Reinforced frame and cutting plates prevent deformation during high-pressure operation.

Automatic pressure adjustment maintains uniform embossing across all sheets.

Fully automatic stripping pins remove waste efficiently, ensuring clean finished sheets.

Top and bottom stripping mechanisms reduce manual handling.

Servo-controlled movement ensures precision alignment.

Quick-change stripping pins allow fast job setup.

The die-cutting platform delivers high-accuracy cutting while minimizing material waste.

Precision crankshaft system distributes pressure evenly.

Durable die-cutting plates extend service life.

Optional tooling setups accommodate specialty shapes and designs.

The delivery unit collects finished sheets efficiently.

Non-stop stacking system improves production speed.

Alignment sensors ensure neat stacking of embossed or die-cut sheets.

Air-cushion options protect delicate materials from scratches.

The machine uses a PLC-based intelligent control system with an HMI touchscreen for easy operation.

Multi-language interface supports global production teams.

Real-time fault display simplifies troubleshooting.

Production memory function stores parameters for repeated jobs.

Regular maintenance ensures optimal machine performance and longevity.

Clean feeders, die-cutting plates, and stripping pins to remove paper dust.

Check lubrication points and apply recommended oil.

Verify air pressure in nozzles and feeders.

Inspect safety sensors and emergency stops for proper function.

Inspect belt and chain tension, adjusting as needed.

Lubricate bearings, guide rails, and moving joints.

Tighten loose mechanical fasteners.

Check stripping system alignment.

Examine die-cutting plates for wear or deformation.

Test PLC and HMI responsiveness.

Inspect electrical wiring for corrosion or loose connections.

Replace lubricants and hydraulic oil according to manufacturer recommendations.

Conduct full system calibration, including embossing pressure and cutting accuracy.

Schedule a certified service inspection.

To maximize efficiency and maintain quality, operators should follow these guidelines:

Material Compatibility: Ensure paperboard or cardboard meets the recommended thickness and density for deep embossing.

Machine Warm-Up: Allow 10–15 minutes for hydraulic and control systems to stabilize before full-speed operation.

Batch Settings: Store parameters for repeated jobs in the HMI memory to reduce setup time.

Safety Compliance: Always use protective equipment and never bypass safety interlocks.

Operator Training: Provide regular training on setup, maintenance, and troubleshooting.

| Task | Frequency | Responsible Personnel |

|---|---|---|

| Clean feeding and stripping system | Daily | Operator |

| Lubricate guide rails and bearings | Daily | Operator |

| Inspect belts, chains, and fasteners | Weekly | Maintenance Staff |

| Check die-cutting plate and embossing pressure | Monthly | Engineer |

| Inspect electrical wiring and sensors | Monthly | Electrician |

| Replace lubricants and hydraulic oil | Annually | Certified Technician |

| Full calibration and inspection | Annually | Service Engineer |

High-Speed Operation: Up to 6,500 sheets per hour.

Precision Embossing: Deep embossing with consistent quality.

Automatic Stripping: Reduces manual labor and waste.

Energy-Efficient: Servo motors and optimized pneumatic system reduce power consumption.

User-Friendly: Touchscreen HMI simplifies setup and monitoring.

Durable Construction: Reinforced steel frame and high-quality components ensure long-term reliability.

Wear gloves, goggles, and non-slip footwear.

Do not operate without safety covers in place.

Keep hands away from cutting and embossing areas.

Press emergency stop immediately if abnormal operation occurs.

Keep production area clean and free of obstacles.

The MP 1060S Automatic Deep Embossing & Stripping & Die-Cutting Machine is a reliable, high-performance solution for modern packaging and printing applications. Its deep embossing capabilities, fully automatic stripping, and precision die-cutting make it suitable for a wide range of materials and applications.

By following recommended maintenance methods, usage guidelines, and safety protocols, operators can achieve long-term reliability, high efficiency, and consistent product quality. With its intelligent control system and robust construction, the MP 1060S is an ideal choice for manufacturers seeking advanced, automated die-cutting and embossing solutions.

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.