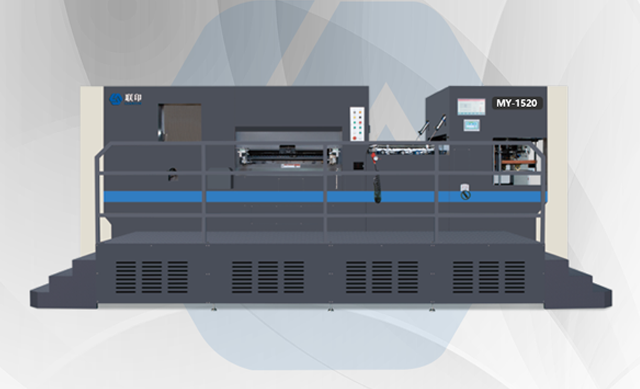

MT 1320S Automatic deep embossing and hot stamping machine

The MT 1320S Automatic Deep Embossing and Hot Stamping Machine is a high-precision, fully automated solution designed for luxury packaging and decorative printing applications. It combines deep embossing and hot foil stamping in a single pass, delivering consistent, high-quality decorative effects.

Equipped with servo-driven sheet feeding, multi-zone temperature control, and an intuitive touch-screen interface, the MT 1320S is ideal for paperboard, cardboard, laminated sheets, and specialty substrates. Common applications include cosmetic boxes, wine packaging, gift boxes, premium brochures, and promotional paper products.

This machine is engineered for high-speed production, precision alignment, and long-term reliability, making it an optimal choice for manufacturers seeking both efficiency and premium finishing quality.

The MT 1320S offers advanced features designed to enhance precision, productivity, and safety:

Combining deep embossing and hot foil stamping reduces manual handling and ensures precise registration. Multi-process integration also increases production speed and minimizes errors.

Ensures micron-level registration and smooth sheet transport, even at high speeds, delivering uniform embossing depth and foil transfer.

The heating system is divided into multiple zones to maintain uniform foil transfer and prevent overheating, ensuring consistent results across the entire sheet.

A cast-iron frame reduces vibration, providing stable embossing pressure and extending machine longevity.

Operators can adjust parameters such as sheet size, stamping depth, pressure, and speed. The interface stores multiple production programs for repeat jobs, reducing setup time.

Equipped with emergency stop buttons, interlocked doors, and overload protection systems, the MT 1320S ensures operator safety and minimizes machine downtime.

Automated foil unwinding and tensioning minimize waste, while quick-change dies reduce setup times and improve operational efficiency.

| Parameter | MT 1320S |

|---|---|

| Max Sheet Size | 1320 × 1000 mm |

| Min Sheet Size | 500 × 400 mm |

| Max Stamping Area | 1300 × 950 mm |

| Max Embossing Depth | 5 mm |

| Max Speed | 5000 sheets/hour |

| Max Pressure | 400 tons |

| Paper/Board Thickness | 150–2500 g/m² |

| Foil Rolls Supported | Up to 4 simultaneous foils |

| Power Supply | 380V / 50Hz / 25 kW |

| Machine Dimensions (L×W×H) | 7200 × 3200 × 2500 mm |

| Net Weight | Approx. 18,500 kg |

Specifications may vary depending on optional configurations or material type.

Proper installation is essential for safe and efficient operation:

Level and reinforced floor capable of supporting 20+ tons.

Ventilated, low-dust environment.

Stable 380V power supply with proper grounding.

Sufficient space for operation and maintenance (at least 1.5 m clearance around the machine).

Carefully remove packaging materials and protective films.

Verify all accessories, spare parts, and manuals are included.

Inspect for any shipping damage or mechanical misalignment.

Place the machine on a level surface using leveling screws.

Ensure the feeding and delivery sections are properly aligned.

Maintain sufficient space for operator access and maintenance.

Connect to the dedicated power supply and check grounding.

Connect pneumatic lines and verify proper operation of air-driven components.

Load sample sheets and perform a trial run.

Adjust parameters such as pressure, temperature, and feeding speed based on the material.

Verify foil transfer, embossing depth, and registration accuracy.

Train operators on touch-screen operation, emergency procedures, and daily maintenance.

Provide manuals and standard operating procedures for reference.

Regular monitoring and quick troubleshooting reduce downtime and maintain production quality.

| Problem | Possible Cause | Solution |

|---|---|---|

| Uneven embossing depth | Misaligned rollers or uneven pressure | Recalibrate pressure zones; check roller alignment |

| Foil tearing | Incorrect tension or poor-quality foil | Adjust foil tension; replace foil with suitable grade |

| Sheet misalignment | Feeding system malfunction | Inspect vacuum feeder; calibrate servo motors |

| Machine stops unexpectedly | Safety interlock triggered | Check interlocked doors; reset emergency stops |

| Inconsistent temperature | Faulty heating element or sensor | Inspect and replace heating element; recalibrate temperature zones |

Note: Always turn off the machine and disconnect power before performing maintenance.

Daily cleaning of feeding, stamping, and delivery areas.

Weekly inspection of rollers, belts, and lubrication points.

Monthly calibration of sensors and alignment checks.

Annual overhaul of electrical, mechanical, and pneumatic systems.

A structured upgrade and maintenance program ensures the MT 1320S maintains peak performance and extended service life.

Update software or HMI firmware for improved performance.

Replace worn rollers or belts.

Clean and lubricate mechanical components.

Check and recalibrate pressure zones.

Inspect servo motors and electronic controllers.

Test safety systems and replace worn sensors.

Complete mechanical inspection and replacement of consumables.

Upgrade heating elements and PLC components as needed.

Perform full trial production run to verify performance standards.

Following a systematic maintenance and upgrade plan minimizes downtime, prevents production losses, and ensures consistent high-quality output.

The MT 1320S is widely used in industries requiring premium finishing effects:

Luxury Packaging: Cosmetic boxes, wine and gift packaging.

Commercial Printing: Book covers, brochures, certificates.

Specialty Products: Labels, embossed logos, promotional cards.

Material Compatibility: Paperboard, cardboard, laminated sheets, PVC, PET.

Its ability to integrate deep embossing and hot stamping ensures elegant tactile and visual effects, enhancing brand identity and product value.

Efficiency: Integrated processes reduce handling and setup time.

Precision: Servo-driven registration ensures perfect alignment.

Cost Savings: Intelligent foil feeding minimizes waste.

User-Friendly Operation: Touch-screen HMI simplifies operation.

Durable Construction: Heavy-duty frame reduces vibration and wear.

Safety: Emergency stops and interlocks protect operators.

Warranty: 12 months covering mechanical and electrical components.

Technical Support: 24/7 online support and on-site service by professional engineers.

Spare Parts: Long-term availability of original parts.

Preventive Maintenance: Optional maintenance contracts for extended machine life.

The MT 1320S Automatic Deep Embossing and Hot Stamping Machine is a versatile, high-performance, and reliable solution for modern printing and packaging operations. Its integrated embossing and hot stamping capabilities, servo-driven precision, and robust construction ensure high-quality decorative finishes while maximizing efficiency and minimizing material waste.

Proper installation, routine maintenance, and adherence to safety protocols ensure long-term reliability, consistent performance, and optimal decorative quality, making the MT 1320S an ideal investment for manufacturers producing premium packaging and promotional products.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.