Technical Parameters

| MT 1450S Automatic deep embossing and hot stamping machine | |

| Model | MT 1450S Automatic Deep Embossing and Hot Stamping Machine |

| Max.paper size | 1450×1100mm |

| Min.paper size | 400×400mm |

| Max.die-cutting size | 1430×1040mm |

| Die-cutting precision | ±0.15mm |

| Max.working pressure | 650T |

| Max.working Speed | 6000P/H |

| Air requirements | 0.7~1.0Mp 0.6m³ |

| Paper thickness | White card/plastic sheet:0.1~1.8mm Grey board:<4mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| First die line distance from template | 15mm |

| Motor power | 18.5Kw |

| Total Power | 67kw |

| Total heating power | 50Kw |

| Servo total power | 19Kw |

| Working power | 40Kw |

| Weight | 25T |

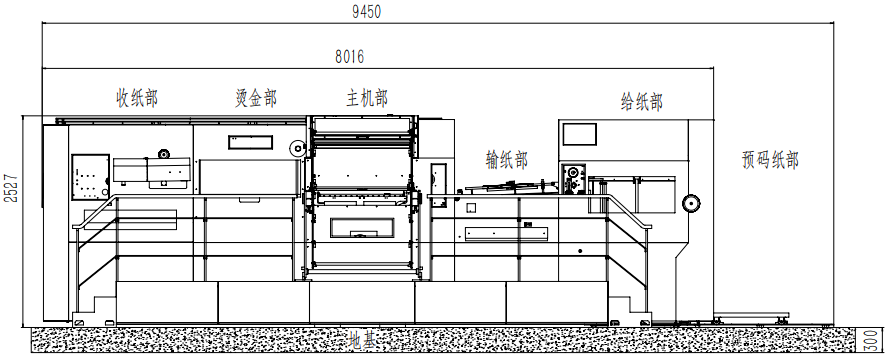

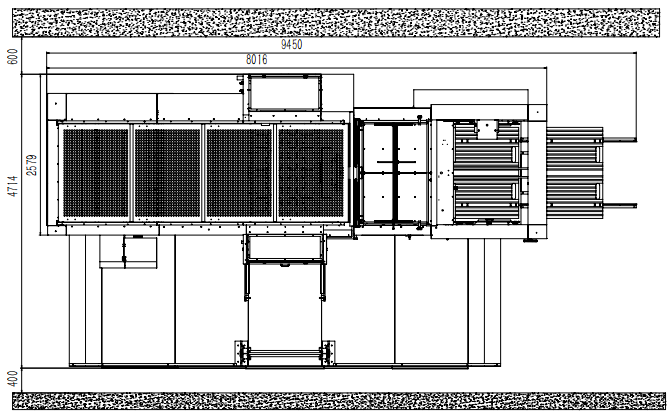

| Dimensions | 9450×2950×2530mm pedal width 2200 |

Sketch

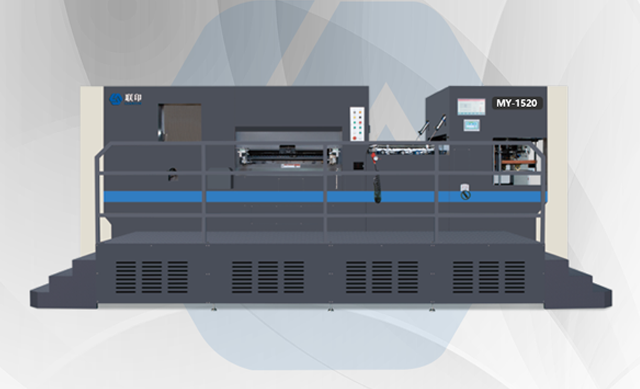

MT 1450S Automatic deep embossing and hot stamping machine

The MT 1450S Automatic Deep Embossing and Hot Stamping Machine is a high-precision, fully automated finishing solution for luxury packaging, promotional products, and specialty printing. It integrates deep embossing and hot foil stamping into a single, streamlined process, providing consistent results, superior registration accuracy, and high production efficiency.

Designed for modern packaging and printing industries, the MT 1450S handles a variety of substrates including paperboard, cardboard, laminated sheets, PVC, and PET, making it suitable for applications such as cosmetic boxes, wine packaging, gift boxes, book covers, and premium marketing materials.

This article explores its technical solutions, structural design, key components, and warranty terms, giving prospective buyers a thorough understanding of its capabilities.

The MT 1450S addresses several challenges in post-press finishing:

Traditional finishing often requires multiple machines for embossing, stamping, and foil application. The MT 1450S combines deep embossing and hot stamping in one automated process, eliminating the need for manual handling and reducing alignment errors.

Servo-driven feeding ensures micron-level alignment, maintaining precise registration across multiple processes. This is particularly beneficial for multi-color foil stamping or complex embossed patterns.

The machine supports a wide range of materials:

Paperboard: 250–2500 g/m²

Cardboard: 300–2500 g/m²

Laminated sheets and specialty substrates

PVC and PET (optional)

Automated sheet feeding, multi-zone temperature control, and quick die/foil change systems increase throughput while minimizing downtime. It can reach speeds of up to 5000 sheets per hour depending on material and design complexity.

The MT 1450S ensures uniform embossing depth, accurate foil transfer, and minimal waste, enhancing product appearance and reducing material costs.

The MT 1450S is engineered with durability, precision, and safety in mind. Its major structural components include:

Constructed from high-strength cast iron, providing stability and vibration resistance.

Supports high-pressure embossing without compromising alignment.

Ensures precise sheet placement and smooth material transport.

Adjustable for different sheet sizes and thicknesses.

Multi-zone temperature control ensures consistent foil transfer.

Prevents overheating and material damage.

High-pressure embossing cylinders deliver uniform depth across the sheet.

Hot stamping unit provides crisp foil transfer with adjustable pressure and temperature.

Touch-screen interface allows operators to set parameters for sheet size, stamping depth, speed, and foil settings.

Stores multiple production programs for repeat jobs.

Emergency stop buttons and interlocked doors.

Overload protection and safety sensors to prevent damage and injury.

A reliable parts list ensures that users can maintain and replace critical components efficiently.

| Component | Description | Function |

|---|---|---|

| Machine Frame | Cast iron | Provides stability, reduces vibration |

| Servo Feeder | High-precision servo motor with vacuum suction | Accurate sheet feeding |

| Embossing Cylinder | Hardened steel rollers | Applies deep embossing |

| Hot Stamping Unit | Multi-zone heating plates | Transfers foil evenly |

| Touch-Screen HMI | LCD touch panel | Control and program management |

| Foil Tensioning System | Adjustable tension rollers | Ensures smooth foil unwinding |

| Delivery Conveyor | Motorized sheet exit | Smooth output collection |

| Safety Interlocks | Door and emergency sensors | Protects operators and machine |

| Pneumatic System | Air-driven actuators | Operates clamping and stamping mechanisms |

| Electrical Cabinet | PLC and servo controllers | Machine automation and monitoring |

Optional accessories may include additional foil rolls, cooling systems, or automated die changers.

| Parameter | MT 1450S |

|---|---|

| Max Sheet Size | 1450 × 1200 mm |

| Min Sheet Size | 500 × 400 mm |

| Max Stamping Area | 1440 × 1150 mm |

| Max Embossing Depth | 5 mm |

| Max Speed | 5000 sheets/hour |

| Max Pressure | 400 tons |

| Paper/Board Thickness | 150–2500 g/m² |

| Foil Rolls Supported | Up to 4 simultaneous foils |

| Power Supply | 380V / 50Hz / 30 kW |

| Machine Dimensions (L×W×H) | 7800 × 3500 × 2600 mm |

| Net Weight | Approx. 22,000 kg |

The MT 1450S comes with comprehensive warranty coverage to ensure reliability and long-term customer satisfaction:

12-month warranty for mechanical and electrical components.

Covers defective parts, labor, and troubleshooting support.

Optional preventive maintenance contracts for 1–3 years.

Annual inspections, calibration, and software updates to maintain peak performance.

Guaranteed availability of original spare parts for at least 10 years.

Rapid shipment options to minimize downtime.

24/7 online support via phone, email, or remote diagnostics.

On-site service by certified engineers if necessary.

Proper installation ensures optimal performance and safety:

Floor Requirements: Level, reinforced floor capable of supporting 25+ tons.

Space: Minimum 1.5 m clearance around the machine.

Power Supply: Dedicated 380V / 50Hz / 30 kW with proper grounding.

Unpacking: Remove all packaging materials and inspect for damage.

Positioning: Align the feeding and delivery sections; level the machine using adjustment screws.

Initial Testing: Load sample sheets, adjust parameters, and perform trial runs.

Operator Training: Educate operators on control panel operation, emergency protocols, and maintenance routines.

To ensure long-term reliability, regular maintenance is recommended:

Daily: Clean feeding and stamping areas; check lubrication.

Weekly: Inspect rollers, belts, pneumatic components; test emergency stops.

Monthly: Calibrate pressure and temperature sensors; inspect bearings and guide rails.

Annually: Complete mechanical and electrical overhaul; test all functions under full production load.

The MT 1450S is suitable for various high-end finishing applications:

Luxury Packaging: Cosmetic boxes, wine packaging, gift boxes.

Commercial Printing: Book covers, brochures, promotional materials.

Specialty Products: Labels, embossed logos, premium marketing materials.

Its precision embossing and foil stamping enhance product appearance and elevate brand value.

The MT 1450S Automatic Deep Embossing and Hot Stamping Machine offers precision, efficiency, and durability for modern packaging and printing industries. Its integrated design, servo-driven feeding, multi-zone temperature control, and robust frame ensure high-quality decorative finishes with minimal waste.

Combined with comprehensive warranty coverage, available technical support, and structured maintenance plans, the MT 1450S is an ideal investment for manufacturers seeking reliable, high-performance finishing equipment for luxury packaging and premium printed products.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.