Technical Parameters

| MY 1050 Automatic Die-Cutting Machine | |

| Model | MY-1050 Automatic Die-Cutting Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370× 270) |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 450T |

| Max.working speed | 8000P/H |

| Air requirementsSpeed | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<2.5mm Corrugated paper:<6mm |

| Gripper rangespeed | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 15Kw |

| Heating power | -- |

| Total power | 21Kw |

| Working power | 16.8Kw |

| Weight | 16.5T |

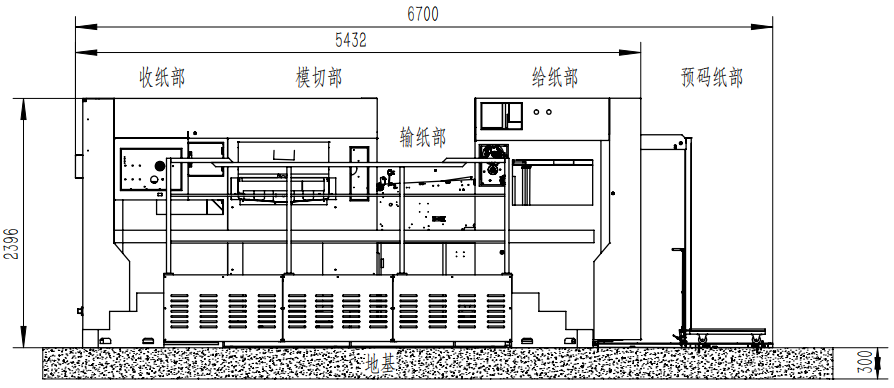

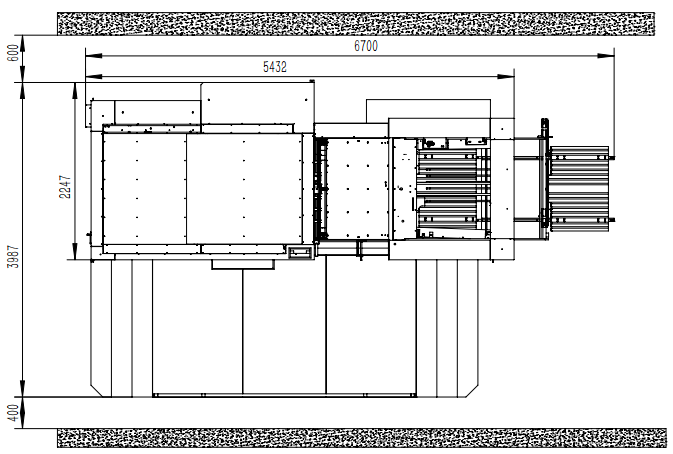

| DimensionsDimensions | 5432×2247×2396mm pedal width 1750mm |

Sketch

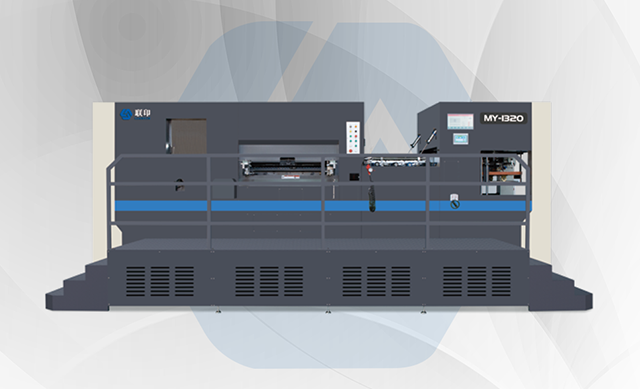

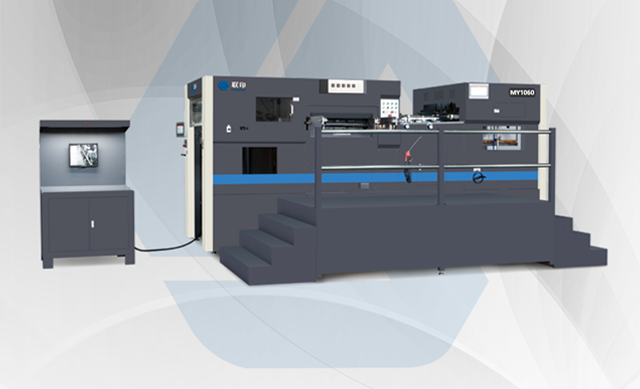

MY 1050 Automatic Die-Cutting Machine: High-Precision Industrial Solution

The MY 1050 Automatic Die-Cutting Machine is a state-of-the-art industrial solution designed for precise die-cutting of paper, cardboard, plastics, and laminated materials. Combining advanced automation, durable construction, and intelligent control systems, the MY 1050 is ideal for packaging, printing, stationery, and decorative product industries. Its fully automated operation ensures high productivity, consistent results, and reduced labor costs.

Fully Automated Operation: Integrated feeding, die-cutting, and stacking functions minimize manual labor.

High-Precision Cutting: Ensures clean, accurate cuts for various materials including cardboard, paper, PVC, and laminated sheets.

User-Friendly Interface: Touchscreen HMI with programmable settings, diagnostics, and operational guidance.

Durable Construction: Heavy-duty steel frame ensures long-term reliability.

Energy Efficiency: Optimized motors and intelligent control systems reduce power consumption while maintaining performance.

Versatile Applications: Suitable for packaging, printing, stationery, and industrial decorative materials.

The MY 1050 provides a comprehensive die-cutting solution:

| Function | Description |

|---|---|

| Die-Cutting | Accurate and repeatable cuts on paper, cardboard, plastics, and laminated materials |

| Automatic Feeding | Continuous feeding system with adjustable guides for various material thicknesses |

| Stacking & Delivery | Automated stacking system with height and alignment adjustment |

| Registration System | Ensures precise alignment of materials for consistent output |

| Safety Features | Emergency stops, protective covers, and sensors for operator protection |

| Specification | MY 1050 Details |

|---|---|

| Max Die-Cutting Area | 1050 mm × 750 mm |

| Max Material Thickness | 8 mm (depending on material type) |

| Die-Cutting Speed | 1,000–2,000 sheets/hour |

| Power Supply | 380V, 50/60Hz, 3-phase |

| Machine Dimensions | 3,100 × 1,650 × 1,850 mm |

| Machine Weight | 2,600 kg |

| Control System | PLC + Touchscreen HMI |

| Safety Features | Emergency stops, protective covers, sensors |

Proper operation ensures efficiency, safety, and long-term machine performance:

Installation and Setup:

Position the machine on a stable, level surface.

Connect to a reliable 380V, 50/60Hz, 3-phase power supply and ensure proper grounding.

Connect compressed air for pneumatic operations if applicable.

Operation:

Load materials and perform a test run to verify die alignment and cutting accuracy.

Adjust pressure and feed settings based on material type and thickness.

Monitor the feed and output system to prevent jams or misalignment.

Shutdown:

Remove all remaining materials from the feed tray.

Turn off the machine and perform cleaning of cutting areas.

Lubricate moving components according to manufacturer instructions.

Safety Instructions:

Never operate without protective guards in place.

Avoid touching moving parts during operation.

Follow emergency stop procedures in case of malfunction.

The MY 1050 is manufactured with strict quality control standards to ensure reliability and precision:

| Quality Check | Description |

|---|---|

| Component Inspection | Verify dimensions, material quality, and functionality of key components |

| Assembly Inspection | Ensure correct assembly and mechanical alignment |

| Operational Testing | Test machine with sample materials for accurate die-cutting and feed consistency |

| Electrical & Control Testing | Validate PLC programming, HMI interface, and sensor functionality |

| Final Audit | Comprehensive inspection before shipment to ensure defect-free operation |

The MY 1050 meets international safety and quality standards, giving users confidence in its reliability and compliance:

| Certification | Description |

|---|---|

| CE | Conforms to EU machinery safety, health, and environmental standards |

| RoHS | Restriction of hazardous substances for eco-friendly production |

| ISO 9001 | Quality management system compliance to ensure consistent product quality |

| Energy Star | Efficient energy usage in industrial machinery applications |

Comprehensive support ensures smooth operation and customer satisfaction:

Installation Support: Professional guidance for machine setup, leveling, and connection to power and air supply.

Operator Training: On-site or remote training for safe and efficient operation.

Technical Support: Remote and on-site troubleshooting assistance.

Spare Parts Supply: Availability of original spare parts for 5 years to minimize downtime.

Preventive Maintenance: Guidelines provided to maximize machine longevity and performance.

Regular maintenance ensures consistent operation and extends machine life:

Daily Maintenance:

Clean feed and cutting areas to remove dust and debris.

Inspect rollers, belts, and moving parts for wear.

Lubricate bearings and gears as recommended.

Weekly Maintenance:

Check die alignment and feed system accuracy.

Inspect pneumatic or hydraulic systems.

Test emergency stops and safety sensors.

Monthly Maintenance:

Conduct full calibration of die-cutting units.

Inspect electrical connections and control panel performance.

Tighten structural bolts and verify mechanical integrity.

Annual Maintenance:

Replace worn parts such as belts, rollers, and hoses.

Inspect servo motors and control systems.

Update software and firmware as necessary.

Maintenance Tips:

Use only manufacturer-approved lubricants and cleaning agents.

Keep the machine in a clean, dry, and dust-free environment.

Maintain a log of all maintenance and repair activities.

The MY 1050 Automatic Die-Cutting Machine is ideal for:

Packaging: Cartons, boxes, and luxury packaging.

Printing Industry: Labels, promotional materials, and decorative prints.

Stationery Manufacturing: Notebooks, folders, and specialty paper products.

Decorative Laminates: Die-cut PVC, PET, and laminated sheets for industrial applications.

High Productivity: Fully automated operation reduces labor and increases output.

Consistent Quality: Precise die-cutting ensures uniform results.

Durable Construction: Heavy-duty design supports long-term industrial use.

Cost Efficiency: Reduced labor, material waste, and energy consumption.

Certified Safety: Conforms to international safety and environmental standards.

The MY 1050 Automatic Die-Cutting Machine provides precision, reliability, and efficiency for modern industrial applications. Certified to international quality and safety standards, it ensures consistent output while minimizing operational costs. Its robust design, user-friendly interface, and comprehensive after-sales support make it ideal for packaging, printing, and stationery industries worldwide.

Investing in the MY 1050 means faster production, superior cut accuracy, and minimal downtime—making it an indispensable solution for industrial die-cutting needs.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.