Technical Parameters

| MY 1320 Automatic Die-Cutting Machine | |

| Model | MY-1320 Automatic Die-Cutting Machine |

| Max.paper size | 1320×980mm |

| Min.paper size | 400×400mm |

| Max.die-cutting size | 1300×970mm |

| Die-cutting precision | ±0.3mm |

| Max.working pressure | 300T |

| Max.working speed | 6000P/H |

| Air requirementsSpeed | 0.6~0.8mp 0.25m³ |

| Paper thickness | Corrugated paper≤8mm |

| Gripper rangespeed | 8mm |

| Motor power | 11Kw |

| Total power | 23Kw |

| Working power | 20Kw |

| Weight | 15T |

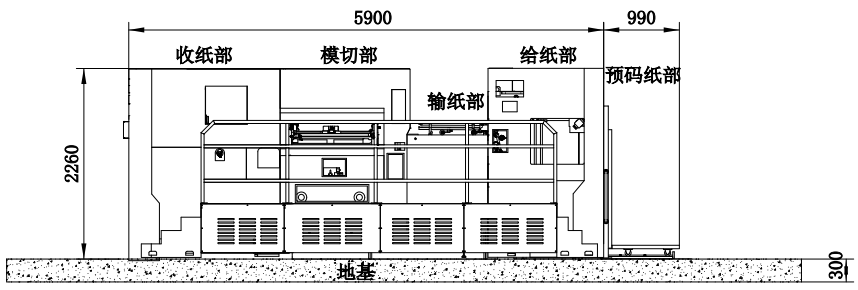

| DimensionsDimensions | 6890×4300×2260mm |

| Optional servo upper paper feeding mode:1320 minimum paper feeding size 370×370MM | |

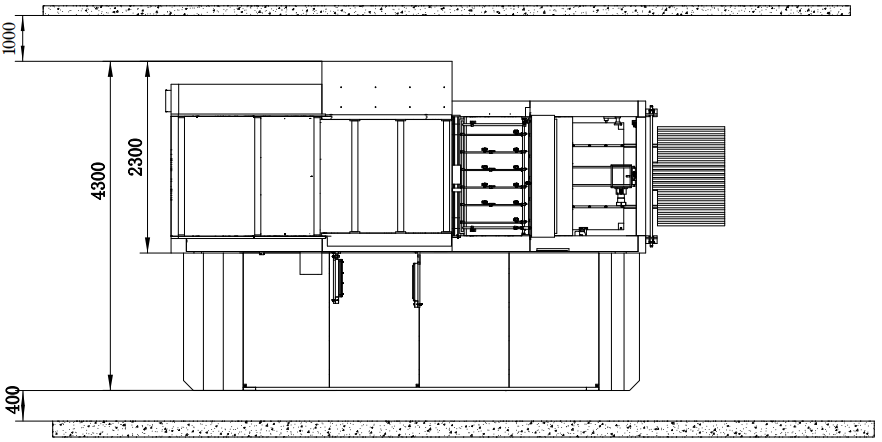

Sketch

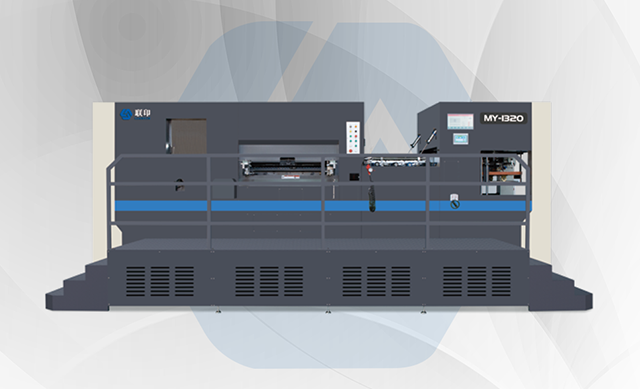

MY 1320 Automatic Die-Cutting Machine: High-Precision Industrial Solution

The MY 1320 Automatic Die-Cutting Machine is a state-of-the-art industrial solution designed for efficient cutting, creasing, and shaping of paper, cardboard, plastics, and laminated materials. Combining automation, precision engineering, and user-friendly operation, the MY 1320 is ideal for packaging, printing, and label manufacturing industries worldwide.

Fully Automatic Operation: Integrated feeding, die-cutting, and stacking functions reduce labor requirements and improve production efficiency.

High-Precision Cutting: Advanced servo control ensures consistent results and minimal material waste.

Versatile Material Handling: Capable of processing cardboard, paper, PVC, PET, and coated materials.

User-Friendly Interface: Touchscreen HMI with programmable settings, diagnostic alerts, and operational guides.

Durable Construction: Heavy-duty steel frame ensures long-term reliability in high-volume production environments.

Energy Efficiency: Optimized motors and systems reduce electricity consumption while maintaining high performance.

Proper packaging ensures safe delivery of the MY 1320 Automatic Die-Cutting Machine:

| Packaging Component | Description |

|---|---|

| Outer Container | Heavy-duty wooden crate reinforced for transport stability |

| Internal Protection | Foam padding, air cushions, and securing straps to prevent vibration |

| Dimensions | 3,400 × 1,700 × 2,000 mm |

| Total Weight | 3,500 kg |

| Additional Items | Instruction manual, tool kit, spare parts, and warranty documents |

| Shipping Method | Suitable for sea, air, or land transport depending on destination |

The packaging is designed to protect the machine during transit while ensuring easy unloading and installation at the destination site.

The MY 1320 adheres to rigorous quality control protocols to ensure safe and reliable operation:

Incoming Component Inspection: All critical parts are inspected for dimensional accuracy and material quality.

Calibration Check: Servo motors, die-cutting units, and feeding systems are calibrated for precise operation.

Performance Testing: Each machine is run with sample materials to verify cutting accuracy, stacking alignment, and operational speed.

Safety Verification: Emergency stops, protective covers, and sensor systems are tested according to international safety standards.

Final Quality Audit: Complete machine inspection is conducted before shipment to ensure defect-free operation.

Regular maintenance ensures long-term reliability and optimal performance of the MY 1320:

Daily Maintenance:

Clean dust and debris from feeding and cutting areas.

Inspect moving parts for wear or abnormal noises.

Lubricate bearings, gears, and other mechanical components as required.

Weekly Maintenance:

Check belt tension, rollers, and die alignment.

Inspect pneumatic systems and air pressure regulators.

Test emergency stops and safety sensors.

Monthly Maintenance:

Perform full inspection of servo motors and control systems.

Verify cutting precision and adjust die-cut units if necessary.

Tighten bolts and check for any structural abnormalities.

Annual Maintenance:

Replace worn-out parts, including rollers, belts, and pneumatic hoses.

Conduct comprehensive calibration of all mechanical and electrical systems.

Review software updates for control panels and HMI systems.

Always follow manufacturer-recommended lubricants and cleaning agents to prevent damage.

Keep the machine in a stable, dry, and dust-free environment to reduce wear.

Train operators in safe handling, adjustment procedures, and troubleshooting.

Maintain a log of maintenance activities to track wear and prevent unexpected downtime.

Inspect spare parts periodically to ensure replacements are ready when needed.

| Specification | MY 1320 Details |

|---|---|

| Max Cutting Area | 1320 mm × 1020 mm |

| Max Material Thickness | 8–10 mm (depending on material type) |

| Cutting Speed | 2,000–4,000 sheets/hour |

| Power Supply | 380V, 50/60Hz, 3-phase |

| Machine Dimensions | 3,400 × 1,600 × 1,800 mm |

| Machine Weight | 3,500 kg |

| Control System | PLC + Touchscreen HMI |

| Safety Features | Emergency stops, protective covers, sensors |

The MY 1320 Automatic Die-Cutting Machine is suitable for a variety of industries:

Packaging: Production of cartons, boxes, and corrugated packaging.

Printing: High-precision die-cut labels, stickers, and promotional materials.

Stationery: Manufacturing folders, notebooks, and paper products.

Plastic & Laminates: Cutting flexible PVC, PET, and coated sheets for industrial use.

Its versatility makes it an essential solution for high-volume, high-precision production lines.

Increased Productivity: Fully automated feeding, cutting, and stacking reduces production time.

Consistent Quality: Precise die-cutting ensures repeatable and uniform results.

Cost Efficiency: Lower labor costs, reduced material waste, and energy savings.

Durable & Reliable: Heavy-duty components and robust design ensure long-term operation.

Easy Maintenance: Modular components and user-friendly access points simplify upkeep.

The MY 1320 Automatic Die-Cutting Machine combines precision, automation, and durability, making it an ideal solution for modern manufacturing operations. Its advanced servo-controlled systems, high-quality construction, and comprehensive maintenance guidelines ensure reliable performance and minimal downtime. Certified to international quality and safety standards, the MY 1320 is a trusted choice for packaging, printing, and material processing industries seeking consistent, high-quality output while reducing operational costs.

Investing in the MY 1320 means faster production, reduced waste, and enhanced efficiency—making it a key asset for industrial die-cutting needs.

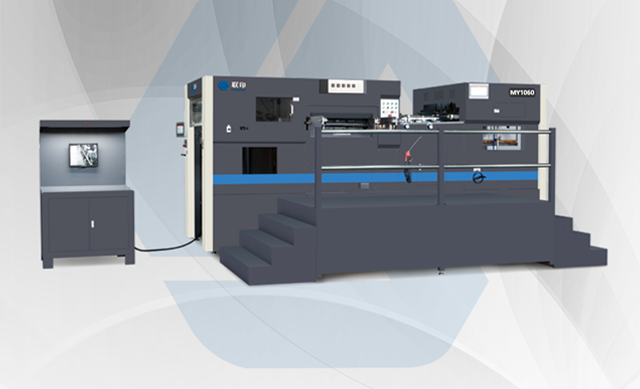

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.