Technical Parameters

| MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine | |

| Model | MP-1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine |

| Max.paper size | 1320×980mm |

| Min.paper size | 400×400mm |

| Max.die-cutting size | 1300×970mm |

| Die-cutting precision | ±0.3mm |

| Max.working pressure | 300T |

| Max.working speed | 5500P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | Corrugated paper≤8mm |

| Gripper range | 8mm |

| Motor power | 11Kw |

| Total power | 26Kw |

| Working power | 22Kw |

| Weight | 17T |

| Dimensions | 7830×4300×2260mm |

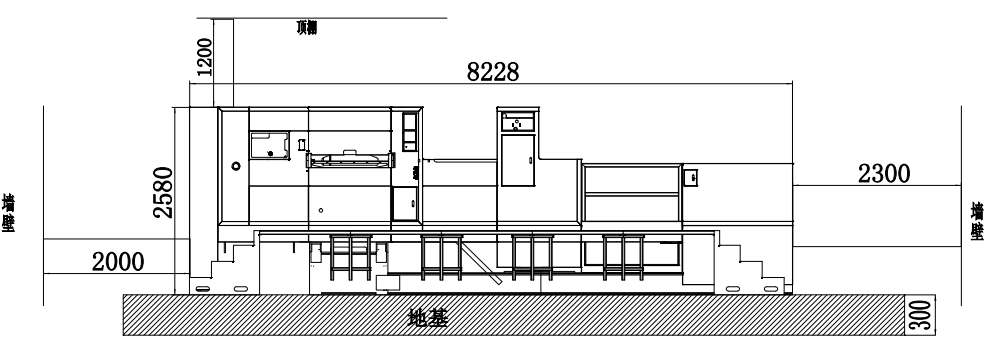

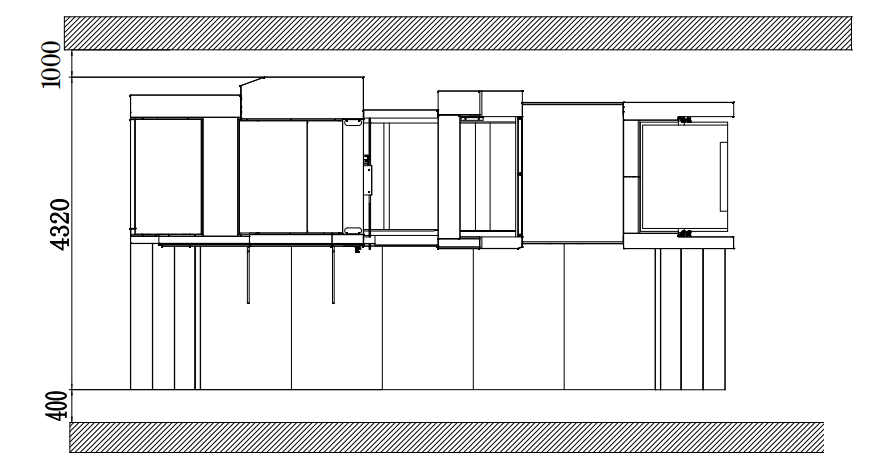

Sketch

MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine

The MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine is designed to meet the growing demands of modern packaging and printing industries. Combining front-edge feeding, lower nozzle air-assist technology, fully automatic stripping, and high-precision die-cutting, the MP 1320 delivers consistent, accurate, and high-speed production. Its robust construction, intelligent control system, and multiple safety features make it suitable for cardboard boxes, corrugated packaging, labels, and paperboard displays, providing manufacturers with efficiency, reliability, and reduced labor costs.

| Feature | Description |

|---|---|

| Model | MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine |

| Max Sheet Size | 1320 × 960 mm |

| Min Sheet Size | 450 × 400 mm |

| Max Cutting Pressure | 350 tons |

| Cutting Speed | Up to 7,500 sheets/hour |

| Die-Cutting Accuracy | ±0.1 mm |

| Feeding System | Front-edge suction with lower nozzle air-assist |

| Stripping Section | Fully automatic top, middle, and bottom stripping |

| Control System | PLC with touchscreen HMI |

| Safety Features | Emergency stops, photoelectric protection, overload sensors |

| Applications | Folding cartons, corrugated boxes, labels, paperboard displays |

Quality assurance is a core aspect of the MP 1320’s manufacturing and delivery process, ensuring reliability, precision, and long-term performance.

Frame Construction: Reinforced steel structure reduces vibration and deformation during high-speed operation.

Precision Machining: All mechanical parts are CNC-machined to tight tolerances, guaranteeing smooth motion and consistent cutting accuracy.

High-Quality Components: Only industrial-grade bearings, servo motors, and pneumatic elements are used to ensure durability.

Every MP 1320 machine undergoes rigorous testing before leaving the factory:

| Test Type | Purpose |

|---|---|

| Mechanical Stability Test | Ensures frame rigidity and minimizes vibration |

| Cutting Accuracy Test | Verifies ±0.1 mm die-cut precision |

| Stripping Efficiency Test | Confirms complete waste removal without manual intervention |

| Safety Inspection | Checks emergency stops, interlocks, and photoelectric sensors |

| Continuous Production Test | 24-hour simulation to ensure operational stability |

Each machine comes with a Quality Inspection Report, Performance Certificate, and User Manual, ensuring transparency and confidence for global customers.

The MP 1320 is designed with environmental sustainability in mind, reducing energy consumption, waste, and noise pollution.

Servo-Controlled Motors: Optimize power usage and reduce energy consumption.

Low-Power Standby Mode: Automatically reduces energy use when the machine is idle.

Efficient Pneumatic System: Uses minimal compressed air while maintaining high performance.

Fully Automatic Stripping: Reduces manual handling and paper waste.

Precise Die-Cutting: Minimizes material scrap by maintaining accurate alignment and pressure.

Recyclable Materials: Most mechanical and structural components are made from recyclable steel and aluminum.

Noise Reduction Design: Reinforced housing and vibration-dampening systems reduce operational noise.

Enclosed Working Area: Protects operators from flying debris and reduces environmental impact.

The MP 1320 integrates a smart PLC control system that displays real-time alerts and fault codes. Understanding common causes and solutions helps reduce downtime.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Sheet misalignment | Improper front-edge feeder or lower nozzle settings | Adjust feeder guides and air pressure |

| Uneven cutting | Worn die plate or uneven pressure | Replace die plate; recalibrate cutting pressure |

| Incomplete stripping | Stripping pins misaligned or blocked | Adjust stripping pins; clean the waste removal system |

| Sudden machine stop | Safety sensor triggered | Check for obstructions; reset sensors |

| Abnormal noise | Loose mechanical parts | Tighten bolts; lubricate moving components |

| Control panel unresponsive | PLC communication error | Restart PLC; inspect wiring and connections |

Regular maintenance and operator training are crucial for preventing recurring issues and ensuring smooth production.

The MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine comes with a comprehensive warranty and after-sales support plan.

Duration: 12 months from delivery or 2,000 working hours (whichever comes first).

Coverage: Mechanical components, electrical systems, and control electronics under normal usage conditions.

Available with service contracts for up to 24 months.

Includes priority technical support and discounted spare parts.

Wear parts such as cutting plates, belts, stripping pins, and seals.

Damage due to improper operation, unauthorized modification, or natural disasters.

Issues caused by unstable power supply or insufficient maintenance.

Installation and Commissioning: On-site setup and calibration by certified engineers.

Remote Technical Assistance: Troubleshooting and firmware updates via internet connection.

Spare Parts Supply: Original replacement parts with fast delivery.

Operator Training: Guidance on safety, maintenance, and efficient operation.

Proper maintenance ensures long-term performance, accuracy, and reliability.

Clean the cutting plate, stripping pins, and guides to remove paper dust.

Check lubrication levels and apply oil where needed.

Verify air pressure in the lower nozzle and feeder system.

Ensure sensors and safety devices are functioning properly.

Inspect belt and chain tension; adjust if necessary.

Lubricate all moving parts, including bearings, guide rails, and grippers.

Examine mechanical fasteners and tighten loose bolts.

Check stripping system alignment and efficiency.

Inspect die-cutting plate flatness and cutting pressure uniformity.

Test PLC and control panel responsiveness.

Examine electrical wiring for wear, corrosion, or loose connections.

Replace lubrication and hydraulic oils as per manufacturer guidelines.

Conduct a full system calibration including die pressure, stripping accuracy, and sheet alignment.

Arrange for an official service inspection by certified engineers.

High-Speed Production: Up to 7,500 sheets per hour without compromising accuracy.

Precision Cutting: ±0.1 mm die-cutting accuracy ensures consistent output.

Automated Stripping: Reduces manual labor and improves safety.

Energy-Efficient Design: Servo motors and optimized pneumatic systems lower operating costs.

User-Friendly Operation: Intuitive HMI with memory recall simplifies repeat production jobs.

Machines are shipped in custom-fitted wooden crates to prevent damage.

Sensitive components are reinforced with shock-absorbing materials.

Store in a dry, ventilated environment away from sunlight and moisture.

For long-term storage, coat exposed metal parts with anti-rust oil.

The MP 1320 Automatic Front Edge & Lower Nozzle & Stripping & Die-Cutting Machine delivers an ideal combination of automation, precision, environmental sustainability, and reliability. Its advanced features, including front-edge feeding, lower nozzle assistance, fully automatic stripping, and intelligent control, make it a standout choice for modern packaging and printing production.

By adhering to recommended maintenance routines, understanding fault causes, and leveraging the comprehensive warranty and after-sales support, manufacturers can maximize productivity, minimize downtime, and achieve consistent high-quality output.

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.