Technical Parameters

| MP 1320 Automatic Fully Stripping And Die-Cutting Machine | |

| Model | MP-1320 Automatic Fully Stripping And Die-Cutting Machine |

| Max.paper size | 1320×980mm |

| Min.paper size | 500×400mm |

| Max.die-cutting size | 1300×960mm |

| Die-cutting precision | ±0.3mm |

| Max.working pressure | 300T |

| Max.working speed | 6000P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | Corrugated paper ≤7mm |

| Gripper range | 7mm |

| Motor power | 11Kw |

| Total power | 25Kw |

| Working power | 22Kw |

| Weight | 17T |

| Dimensions | 8288×4320×2580mm |

| Optional servo upper paper feeding mode:1320 minimum paper feeding size 370×370mm | |

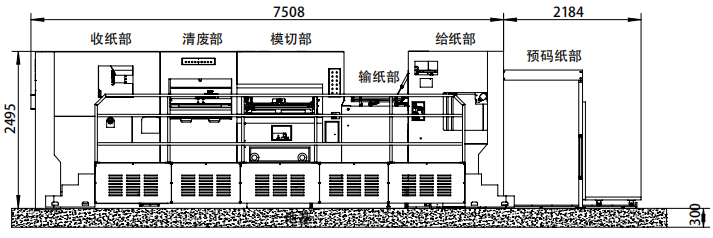

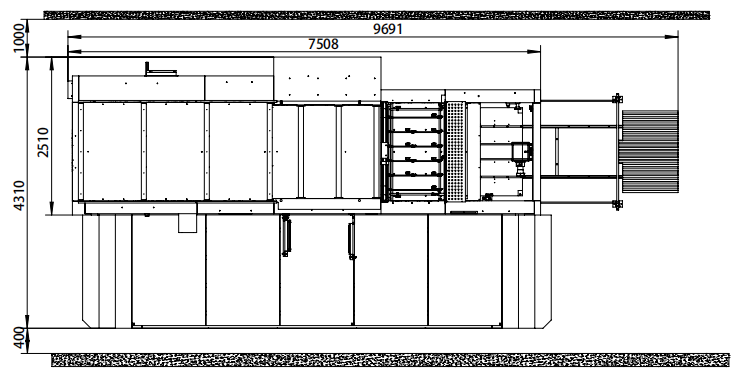

Sketch

MP 1320 Automatic Fully Stripping and Die-Cutting Machine

The MP 1320 Automatic Fully Stripping and Die-Cutting Machine represents a new generation of intelligent paper converting equipment, designed to meet the growing demand for precision, speed, and efficiency in modern packaging production. With its advanced automation system, stable mechanical structure, and user-friendly control interface, the MP 1320 ensures accurate die-cutting and full stripping for paperboard, cardboard, and corrugated materials.

This model is widely used in industries such as packaging, printing, stationery, and labeling, offering superior results in both short-run and high-volume production environments. Built with reliability and performance in mind, the MP 1320 provides consistent cutting accuracy and reduced waste—helping manufacturers improve productivity while maintaining excellent quality standards.

| Feature | Description |

|---|---|

| Model Name | MP 1320 Automatic Fully Stripping and Die-Cutting Machine |

| Max Sheet Size | 1320 × 960 mm |

| Min Sheet Size | 450 × 400 mm |

| Max Cutting Pressure | 350 tons |

| Cutting Speed | Up to 7,500 sheets/hour |

| Feeding System | Automatic continuous feeding with front and side registration |

| Stripping Section | Fully automatic stripping mechanism with adjustable pins |

| Die-Cutting Accuracy | ±0.1 mm |

| Main Drive System | High-precision crankshaft with pneumatic clutch |

| Control System | PLC + touchscreen HMI |

| Safety System | Emergency stop, photoelectric protection, automatic alarm |

| Applications | Folding cartons, corrugated boxes, labels, luxury packaging |

The MP 1320 ensures exceptional cutting accuracy through its reinforced frame design, servo-controlled drive, and advanced positioning sensors. The cutting plate and pressure system are precisely calibrated to minimize deviation, allowing smooth die-cutting even on thick or laminated substrates.

Reinforced mechanical base minimizes vibration and deformation.

Servo motor control enables stable pressure adjustment during cutting.

Precision registration system ensures perfect alignment between die and sheet.

The machine’s fully automatic stripping section effectively removes internal waste and side scraps without manual intervention. The stripping frame is adjustable, allowing quick setup for various layouts and product formats.

Top, middle, and bottom stripping structure ensures complete removal.

Quick-change stripping pins improve setup speed.

Reduced manual work, improving efficiency and safety on the production line.

The PLC touchscreen control panel simplifies operation, allowing real-time monitoring of machine status, production speed, and fault information. Operators can easily adjust parameters and save job settings for repeat production runs.

Intuitive display interface in multiple languages.

One-click job recall for repeated orders.

Automatic fault diagnosis for quick troubleshooting.

Safety is a top priority in the MP 1320’s design. Multiple protection mechanisms ensure operator security and equipment reliability throughout production.

Emergency stop buttons at multiple points.

Photoelectric safety sensors detect foreign objects or human presence.

Automatic pressure release system prevents overloading.

Protective enclosure reduces noise and isolates moving parts.

Operating the MP 1320 Automatic Fully Stripping and Die-Cutting Machine requires adherence to strict safety procedures to prevent accidents and ensure consistent performance.

Only trained personnel should operate or maintain the equipment.

Always wear personal protective equipment (PPE) such as gloves, safety glasses, and protective shoes.

Avoid loose clothing, jewelry, or long hair near moving parts.

Before starting, ensure all safety guards are properly in place.

Verify air pressure and lubrication systems are functioning correctly.

During shutdown, turn off the main power supply and release the cutting pressure.

Familiarize yourself with the emergency stop buttons and safety locks.

In case of unusual noise, vibration, or smell, stop the machine immediately.

Report all incidents to a supervisor or maintenance engineer before restarting.

Never open electrical panels while the machine is powered.

Disconnect the main power before performing maintenance or cleaning.

Avoid touching high-temperature or rotating components during operation.

Proper maintenance ensures the long-term reliability and precision performance of the MP 1320. Routine inspection and preventive care can significantly extend the lifespan of key components.

Clean the cutting plate and die area after each shift to remove paper dust.

Check oil levels in the lubrication system.

Inspect air pressure gauges and ensure consistent air supply.

Verify sensors and limit switches for responsiveness.

Lubricate guide rails, bearings, and chains using recommended oil.

Check tension of drive belts and adjust if necessary.

Inspect gripper bars for wear or deformation.

Tighten all bolts and fasteners to prevent vibration-related loosening.

Examine die-cutting plate flatness and pressure balance.

Inspect electrical connectors and control cables for corrosion or damage.

Test safety sensors and interlocks to ensure functionality.

Clean and calibrate the touchscreen control interface.

Replace hydraulic and lubrication oil as per manufacturer recommendations.

Conduct a comprehensive performance test on cutting pressure, registration, and stripping speed.

Calibrate the servo drive system to maintain ±0.1 mm cutting accuracy.

Schedule an official service inspection from authorized technicians.

| Maintenance Task | Frequency | Responsible Person |

|---|---|---|

| Cleaning of cutting area | Daily | Operator |

| Lubrication check | Daily | Operator |

| Belt tension inspection | Weekly | Maintenance staff |

| Electrical inspection | Monthly | Electrician |

| Servo calibration | Every 6 months | Technical engineer |

| Full system inspection | Annually | Authorized technician |

In the event of machine faults, the MP 1320’s smart control system provides real-time error codes to help diagnose and resolve issues quickly. Below are common fault causes and corrective actions.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Sheet misalignment | Incorrect feeder setup | Re-adjust front and side guides |

| Uneven cutting | Worn die plate or uneven pressure | Replace die plate / re-calibrate pressure |

| Poor stripping | Incorrect stripping pin layout | Adjust stripping setup and timing |

| Machine stops suddenly | Safety sensor triggered | Check for obstacles / reset sensors |

| Abnormal noise | Loose mechanical parts | Tighten bolts and lubricate joints |

| Touchscreen unresponsive | Control system lag | Reboot PLC / check cable connections |

If the fault persists after following the above steps, contact an authorized service provider for inspection and repair.

Each MP 1320 machine undergoes rigorous quality inspection and functional testing before delivery to ensure stable performance under production conditions.

Frame rigidity and vibration testing

Die-cutting plate pressure uniformity inspection

Long-duration continuous cutting stability test

PLC and inverter communication validation

Safety interlock verification

Emergency stop function testing

Every machine is delivered with a Quality Inspection Certificate and Performance Report, confirming compliance with international safety and production standards such as:

ISO 9001 Quality Management System

CE Safety Certification

EN 1010 Printing Machinery Safety Standard

The MP 1320 Automatic Fully Stripping and Die-Cutting Machine is backed by a 12-month comprehensive warranty from the date of delivery, covering:

Mechanical parts under normal operation

Electrical components (PLC, inverter, sensors, and display)

Technical support for installation, setup, and training

Damage caused by improper operation, unauthorized modification, or natural disasters.

Wear parts such as cutting plates, belts, or seals.

Use of non-original replacement parts.

For extended warranty or spare part service, customers can contact the manufacturer’s after-sales service center.

To ensure smooth operation and customer satisfaction, professional technical support is available throughout the machine’s service life.

Installation and Commissioning: On-site setup and calibration by certified engineers.

Operation Training: Comprehensive guidance on machine operation and safety.

Remote Technical Support: Online diagnostics and software updates.

Spare Parts Supply: Original replacement components with fast delivery.

Ensure the machine is properly packed and secured before shipping.

Avoid tilting or stacking during transport.

Store in a dry, ventilated area, away from direct sunlight and moisture.

Before long-term storage, coat metal surfaces with anti-rust oil.

The MP 1320 Automatic Fully Stripping and Die-Cutting Machine offers a perfect combination of automation, precision, and safety, making it an essential piece of equipment for modern packaging production lines. Its user-friendly interface, stable performance, and low maintenance requirements help businesses achieve high productivity with minimal downtime.

By following the recommended safety instructions and maintenance schedule, operators can ensure long-term efficiency, consistent cutting quality, and reliable machine operation for years to come.

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.