Technical Parameters

| MP 1520 Automatic Fully Stripping And Die-Cutting Machine | |

| Model | MP-1520 Automatic Fully Stripping And Die-Cutting Machine |

| Max.paper size | 1520×1110mm |

| Min.paper size | 500×450mm |

| Max.die-cutting size | 1500×1100mm |

| Die-cutting precision | ±0.3mm |

| Max.working pressure | 300T |

| Max.working speed | 5500P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | Corrugated paper≤7mm |

| Gripper range | 10mm |

| Motor power | 11Kw |

| Total power | 25Kw |

| Working power | 22Kw |

| Weight | 18T |

| Dimensions | 9516×4951×2398mm |

| Optional servo upper paper feeding mode:1520 minimum paper feeding size 400×400mm | |

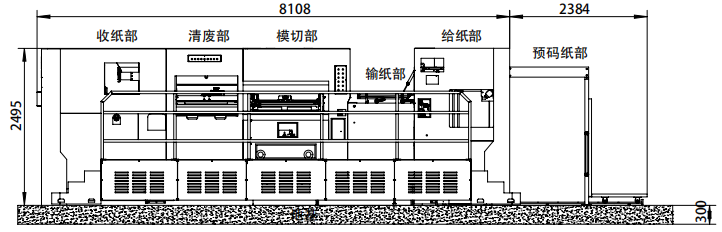

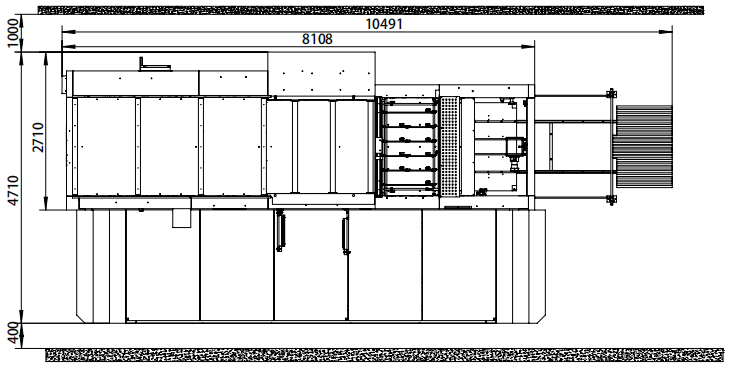

Sketch

MP 1520 Automatic Fully Stripping and Die-Cutting Machine

The MP 1520 Automatic Fully Stripping and Die-Cutting Machine is an advanced high-speed die-cutting system designed to meet the growing demand for efficiency, precision, and automation in the global packaging and printing industries. With a fully automatic stripping mechanism, robust construction, and intelligent control interface, this machine delivers exceptional cutting accuracy and reliability for large-format production.

Whether used for cardboard, corrugated board, or laminated paper, the MP 1520 ensures smooth feeding, precise die-cutting, and complete waste removal in a single pass—helping manufacturers reduce labor costs, improve output consistency, and enhance production flexibility.

| Feature | Description |

|---|---|

| Model | MP 1520 Automatic Fully Stripping and Die-Cutting Machine |

| Max Sheet Size | 1520 × 1060 mm |

| Min Sheet Size | 500 × 450 mm |

| Max Cutting Pressure | 350 tons |

| Max Speed | Up to 7,000 sheets/hour |

| Die-Cutting Accuracy | ±0.1 mm |

| Stripping System | Fully automatic top, middle, and bottom stripping |

| Drive System | High-precision crankshaft with pneumatic clutch |

| Control System | PLC with HMI touchscreen |

| Safety Functions | Emergency stops, photoelectric protection, overload sensors |

| Applications | Folding cartons, corrugated packaging, paperboard displays, labels |

The MP 1520 integrates modern engineering design with a focus on stability, efficiency, and safety. Each section of the machine is meticulously constructed to ensure high precision, durability, and smooth operation under continuous production conditions.

The automatic feeder unit is equipped with high-speed suction and alignment mechanisms that guarantee stable sheet feeding even at maximum running speed.

Non-stop feeding system allows continuous production without downtime.

Front and side registration ensures accurate sheet positioning.

Adjustable suction nozzles adapt to different paper types and thicknesses.

At the heart of the MP 1520 lies a high-strength die-cutting platform driven by a precision crankshaft system. The large-format cutting frame ensures even pressure distribution, making it suitable for heavy-duty packaging materials.

Reinforced steel frame minimizes vibration and deformation.

Pneumatic clutch system provides smooth start and stop control.

Automatic pressure adjustment enhances cutting consistency.

The fully automatic stripping mechanism efficiently removes internal and external waste after die-cutting, ensuring clean, finished blanks.

Three-layer stripping structure (top, middle, bottom) ensures complete waste removal.

Quick-change stripping pins allow for easy job setup.

Servo-driven movement improves precision and reduces operator workload.

The delivery unit collects finished sheets neatly and safely.

Non-stop collection system improves efficiency.

Sheet counter and alignment sensors ensure consistent stacking.

Optional air cushion device protects delicate materials.

The MP 1520 features a PLC-based intelligent control system with a touchscreen HMI interface for real-time monitoring and parameter adjustment.

Multi-language menu interface for global users.

Automatic fault display and alarm system for easy troubleshooting.

Memory function to store production parameters for repeat orders.

Precision and Speed – Advanced servo and pneumatic systems ensure ±0.1 mm accuracy even at high speed.

Reduced Manual Labor – Fully automatic stripping and delivery minimize operator intervention.

Durability and Longevity – Heavy-duty construction and high-quality components ensure long-term performance.

User-Friendly Operation – Touchscreen controls and simplified setup reduce training time.

Low Maintenance Design – Modular layout allows easy cleaning and component access.

To provide customers with peace of mind, the MP 1520 Automatic Fully Stripping and Die-Cutting Machine includes a comprehensive warranty and technical support package.

Standard Warranty: 12 months from the date of delivery or 2,000 working hours (whichever comes first).

Extended Warranty: Available upon request with a maintenance agreement.

| Covered Items | Warranty Description |

|---|---|

| Mechanical Parts | Defects in materials or manufacturing under normal use. |

| Electrical Components | PLC, inverters, and sensors are covered for one year. |

| Technical Assistance | Remote or on-site support during the warranty period. |

| Software Updates | Free firmware upgrades and diagnostic updates. |

Wear parts such as cutting plates, belts, and seals.

Damage due to improper use, modification, or unauthorized repairs.

Failure caused by power instability or lack of maintenance.

Natural disasters or transportation damage.

Online technical support for immediate troubleshooting.

Spare parts availability with short delivery times.

On-site service by professional technicians when necessary.

Regular maintenance ensures optimal performance and extends the lifespan of the MP 1520. Below are the daily maintenance routines recommended by technicians:

Check that all safety guards and covers are in position.

Verify oil level and air pressure indicators.

Clean the cutting plate surface and remove debris.

Ensure die and paper alignment are correct before starting.

Observe for any abnormal noise or vibration.

Ensure the stripping system is working smoothly.

Monitor temperature and pressure readings for stability.

Keep the working area free of paper dust.

Clean gripper bars and guide rails using a dry cloth.

Turn off main power and air supply.

Apply anti-rust oil on exposed metal surfaces.

Record daily production and machine condition in a maintenance log.

| Task | Frequency | Responsible Personnel |

|---|---|---|

| Clean dust and debris | Daily | Operator |

| Lubricate moving parts | Daily | Operator |

| Inspect die-cutting pressure | Weekly | Maintenance Staff |

| Check belt tension | Weekly | Maintenance Staff |

| Inspect electrical wiring | Monthly | Electrician |

| Replace filters and oil | Every 6 months | Engineer |

| Calibrate servo and sensors | Every 12 months | Certified Technician |

To ensure stable operation and reduce unplanned downtime, the following preventive maintenance recommendations should be followed:

Lubrication plays a crucial role in maintaining the smooth functioning of mechanical components. Use only manufacturer-recommended lubricants and follow specified intervals.

Guide rails, bearings, and joints should be lubricated daily.

Crankshaft and cam systems require inspection every week.

Replace lubrication oil every six months or 3,000 hours of operation.

Check all electrical connectors for looseness or corrosion.

Ensure sensors and switches respond correctly.

Regularly test emergency stop buttons and interlocks.

Avoid high-humidity environments to prevent short circuits.

Drain condensed water from air filters daily.

Maintain air pressure between 0.6–0.8 MPa for consistent performance.

Replace air filters every three months.

Keep the cutting plate surface clean and flat.

Replace worn or damaged dies immediately.

Store dies in a dry and protected environment when not in use.

Only qualified personnel should operate or maintain the machine.

Operators should receive periodic training on safety, cleaning, and calibration.

Keep a maintenance record for tracking service history and component changes.

Safety is integral to the design of the MP 1520. The following guidelines must be observed during operation and maintenance:

Always wear safety gear such as gloves, goggles, and non-slip shoes.

Do not operate the machine without safety covers installed.

Avoid placing hands near the cutting area or moving grippers.

Press the emergency stop button immediately in case of abnormal operation.

Keep work areas clean and dry to avoid slipping hazards.

Disconnect the main power before performing maintenance.

Every MP 1520 unit is manufactured under strict ISO 9001 quality management and CE safety certification standards.

Mechanical stability test: Ensures machine rigidity and precision.

Cutting accuracy test: Confirms ±0.1 mm repeatability.

Safety inspection: Verifies function of emergency stops and interlocks.

Continuous operation test: 24-hour simulation for performance verification.

Upon delivery, each machine comes with a quality inspection report and a factory acceptance certificate, verifying compliance with industry standards and technical specifications.

The machine is securely packed in a fumigation-free wooden crate for safe transport.

Sensitive parts are reinforced with shock-absorbing materials.

Avoid exposure to moisture, dust, or direct sunlight during storage.

For long-term storage, coat metallic components with anti-rust oil and cover the machine with a protective sheet.

The MP 1520 Automatic Fully Stripping and Die-Cutting Machine offers unmatched reliability, precision, and automation for today’s packaging and printing enterprises. Its intelligent control system, fully automated stripping unit, and durable construction make it a cost-effective solution for companies looking to boost productivity and quality.

By following the recommended maintenance routines, adhering to safety guidelines, and utilizing the comprehensive warranty support, customers can expect consistent high performance and long-term value from their MP 1520 machine.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.